Wall Mounted Jib Crane

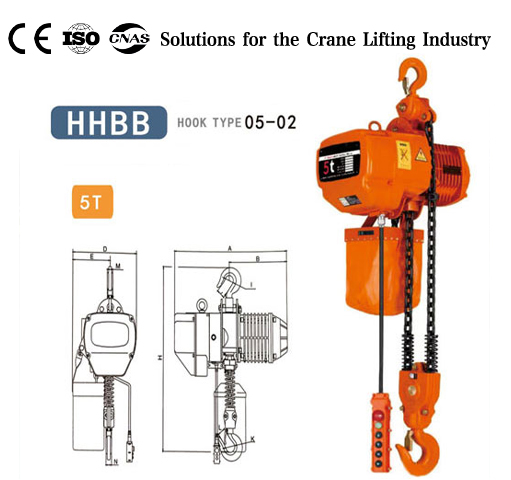

Capacity: up to 5 ton

Arm length: up to 10 m

Lifting height:up to 20m

Work duty: M3-M5

Rotation angle: 120-360°

Raged voltage: 220V~690V, 50-60Hz, 3ph AC

Crane control mode: Floor control / Remote control

Description

Wall Mounted Jib Crane can be installed directly on the profile steel, concrete column, wall or other self-standing equipment without occupying the floor space. The column that support the horizontal beam is instead by the wall that provided by the factory or plant itself. Apparently, it offers an economical alternative to free standing jib crane. It is capable of 200 degree rotation with the capacities up to 5 tons and arm length up to 7 m. Our wall mounted jib cranes can be installed very close to the underside of the lowest obstruction and squeeze into the tightest plant, warehouse or other industrial space. So, the scope of available installation space is bigger. It can also offer maximum lift height for the hoist and greatest amount of clearance.

The slewing, long travel and hosting motions of these systems can be either manually operated or powered making them suitable for a range of applications across various sectors.

Features

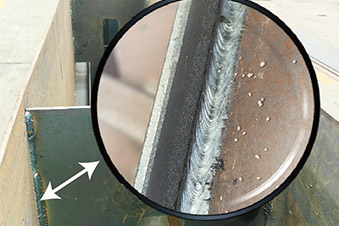

High quality steel

Easy to install

Excellent smooth running properties thanks to low moving mass

High working speed and positioning accuracy

It can sharply increase the productivity of the plant by working as a complement for overhead crane and gantry crane.

Tailor jib crane to meet the special capacities and longer spans.

The utilization rate of spacing is unrival high.

Offer the optimal highest hook position.

Technical Data

| Serials | Lifting capacity(t) | Arm length(m) | Lifting height m |

| 1 | 10 | 10 | 9 |

| 2 | 5 | 10 | 8 |

| 3 | 3 | 10 | 9 |

| Lifting capacity (kg) | Front outreach distance (m) | |||||

| Specification | 2 | 3 | 4 | 5 | 6 | 7 |

| 80 | ||||||

| 125 | ||||||

| 250 | ||||||

| 500 | ||||||

| 1000 | ||||||

| Lifting capacity (kg) | Front outreach distance (m) | ||||||||||

| Specification | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 80 | |||||||||||

| 125 | |||||||||||

| 250 | |||||||||||

| 500 | |||||||||||

| 1000 | |||||||||||

| 1600 | |||||||||||

| 2000 | |||||||||||

| 2500 | |||||||||||

| 3200 | 10.5 | ||||||||||

| 4000 | 9.5 | ||||||||||

| 5000 | 8.5 | ||||||||||

| 6300 | |||||||||||

| 8000 | 5.5 | ||||||||||

| 10000 | |||||||||||

Components

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.