Home > Crane Parts > Single stage Slip wire

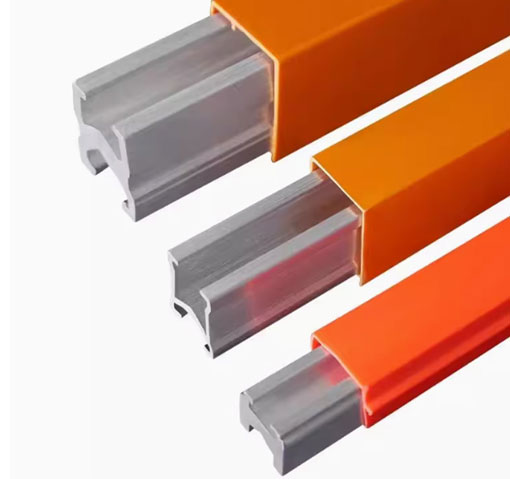

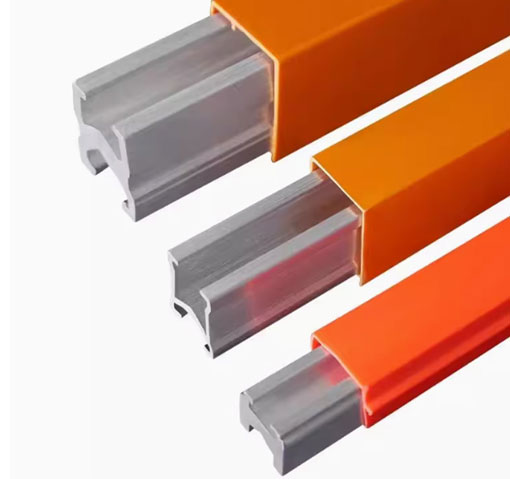

Single stage Slip wire

Efficient and durable

Anti-corrosion and wear-resistant

Support customization

Slipline accessories: Connection accessories include hanger clips, connector/retaining, protective boxes, and brackets. connector and protective box every 6 meters (one) with a. Hanging card and bracket every 1.5 meters with a.

Description

H-type single-stage sliding contact line, is a new type of mobile machinery and equipment feed power supply system, the conductor for the aluminum alloy profile, the outer sheath is made of polyvinyl chloride raw materials, to play the role of rain, dust, electric shock prevention safety.

Features

1、Safety and reliability, even with finger contact there is no danger of electric shock, in line with IP23standards

2、Energy saving and consumption reduction, the use of specially formulated aluminum alloy profiles for the conductor; resistance is small, can greatly reduce the loss of electrical energy.

3、Sheath and accessories are universal.

4、Long service life, the conductor sheath also adopts a unique formula, which greatly extends the service life of the unipolar sliding contact line system.

5、Collector can move in three-dimensional space, which can meet the uninterrupted power supply of the power supply equipment; double insulation design, safer and more reliable work

6、new materials, new technology, new technology to ensure that the product has a higher corrosion resistance, acid resistance,weather resistance and working temperature range, working performance is more secure and reliable!

Technical Data

| Product specification: | 200A 250A 320A 400A....1600A 2000A 3000A |

| Product material: | high quality aluminum |

| Slip line length: | 6 meters a |

Components

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.