Home > Products > Overhead Crane > LD Single Beam Bridge Crane

LD Single Beam Bridge Crane

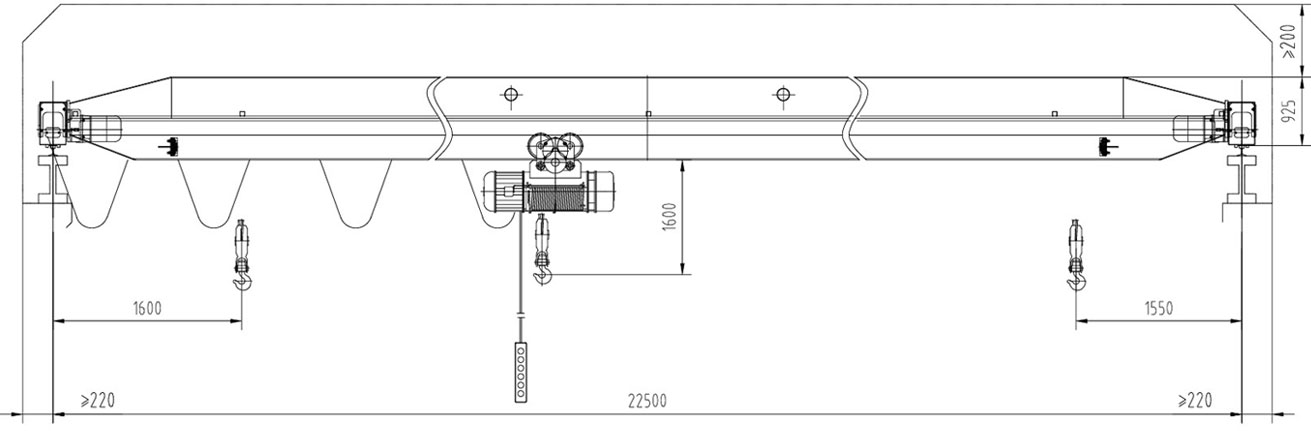

The Yangyumech electric single-girder overhead traveling crane features a reasonable structure and strong rigidity of the whole machine. The whole machine is used in conjunction with the electric hoist. Its lifting capacity is 1 - 60t, the working level is A3 - A5, and the working environment temperature is -25 - 40℃. The product is widely used in different occasions such as factories, warehouses, and material yards. According to the needs of different users, this product has two operation forms: ground operation and control room operation.

Capacity: 1t-60t

Customized:YES

Description

Single girder overhead crane is our flexible crane for almost any application. Even in buildings with low ceilings effective material flow solutions can be achieved. The single girder overhead travelling crane lifts safe working loads to 12,000 kg. The crane bridge girders are adapted individually to the ceiling construction with different connection variants. This allows optimum utilisation of space.

Single girder overhead cranes adapt to different building applications due to their various main girder connection variants. Favourable crane dimensions help to reach optimal highest hook positions. If lifting height is the decisive factor then a single girder crane with side-running trolley is the right choice. The lifting height can be increased further by using a cantilever crab with extremely low headroom or a chain hoist in extra short headroom trolley design.

The single-girder travelling crane is also a good choice for special solutions: The accessories and components offer specialised additional equipment to satisfy your requirements.

Features

Flexible, adaptable through different installation variants

Low-maintenance, low-noise direct drive with disc brake and centrifugal mass

Smooth starting and braking characteristics: with frequency inverter as an option

Explosion-proof versions or off-standard solutions through engineering

Most economical option for light to medium-duty cranes

Better hook approach for both trolley travel and bridge travel

Ideal for workshops, warehouses, material yards, and manufacturing and production facilities

Lighter load on runway rails or beams means less wear on the beams and end truck wheels over time

Great for facilities with low headroom

Technical Data

| capacity(t) | span(m) | lifting height (m) |

working group | lifting speed (m/min) | weight | track | power rate(kw) | max wheel load(kw) | H | h | A | W | B | |

| trolley (kg) | entire machine(kg) | |||||||||||||

| 1 | 9.5 | 6 9 12 18 |

A5 (2m) | 08/5 | 376 | 958 | P24 | 4.58 | 8.76 | 710 | 260 | 183 | 1500 | 1928 |

| 11 | 1599 | 9.51 | ||||||||||||

| 12.5 | 1723 | 10.45 | ||||||||||||

| 16 | 2220 | 11.58 | 693 | 447 | 2000 | 2428 | ||||||||

| 19.5 | 2835 | 13.06 | 570 | 497 | 2500 | 2928 | ||||||||

| 22.5 | 3532 | 14.62 | 652 | 497 | 3000 | 3764 | ||||||||

| 24 | 3774 | 16.1 | 652 | 508 | ||||||||||

| 2 | 9.5 | 6 9 12 15 18 |

A5 (2m) | 08/5 | 376 | 1625 | P24 | 4.58 | 13.5 | 755 | 260 | 183 | 1500 | 1928 |

| 11 | 1784 | 14.46 | ||||||||||||

| 12.5 | 1970 | 15.54 | ||||||||||||

| 16 | 232 | 17.47 | 575 | 447 | 2000 | 2428 | ||||||||

| 19.5 | 3175 | 18.93 | 655 | 497 | 2500 | 2928 | ||||||||

| 22.5 | 3726 | 20.39 | 735 | 497 | 3000 | 3764 | ||||||||

| 24 | 4016 | 22.38 | 735 | 508 | ||||||||||

| 3 | 9.5 | 6 9 12 15 18 |

A5 (2m) |

08/5 | 376 | 1802 | P24 | 4.58 | 18.96 | 755 | 260 | 183 | 1500 | 1928 |

| 11 | 2168 | 20.11 | ||||||||||||

| 12.5 | 2350 | 21.85 | ||||||||||||

| 16 | 2872 | 23.51 | 625 | 452 | 2000 | 2428 | ||||||||

| 19.5 | 3854 | 4.94 | 25.45 | 675 | 492 | 2500 | 2928 | |||||||

| 22.5 | 4549 | 27.06 | 755 | 512 | 3000 | 3464 | ||||||||

| 24 | 4855 | 30.6 | 755 | 541 | ||||||||||

| 5 | 9.5 | 6 9 12 15 18 |

A5 (2m) |

08/5 | 531 | 2318 | P24 | 7.84 | 28.2 | 666 | 505 | 183 | 1500 | 2674 |

| 11 | 2566 | 29.76 | ||||||||||||

| 12.5 | 2816 | 31.8 | 666 | 565 | ||||||||||

| 16 | 3673 | 33.84 | 776 | 665 | 2000 | 2500 | ||||||||

| 19.5 | 4364 | 8.24 | 35.62 | 776 | 665 | 2500 | 3000 | |||||||

| 22.5 | 6392 | 39.78 | 896 | 3000 | 3500 | |||||||||

| 24 | 5754 | 42.62 | 946 | |||||||||||

| 10 | 9.5 | 6 9 12 15 18 |

A5 (2m) |

08/5 | 928 | 3260 | P38 | 12.66 | 51.85 | 762 | 762 | 183 | 1700 | 2238 |

| 11 | 3596 | 54.44 | 842 | |||||||||||

| 12.5 | 3896 | 57.7 | 892 | |||||||||||

| 16 | 4889 | 60.83 | 878 | 876 | 2000 | 2538 | ||||||||

| 19.5 | 5913 | 64 | 948 | 976 | 2500 | 3038 | ||||||||

| 22.5 | 7527 | 67.26 | 980 | 1006 | 3000 | 3538 | ||||||||

| 24 | 7975 | 71.36 | 1020 | 1006 | ||||||||||

| 16 | 9.5 | 6 9 12 15 18 |

A5 (2m) |

0.66/4 | 1420 | 4284 | P43 | 19.48 | 83.1 | 820 | 862 | 183 | 1700 | 2238 |

| 11 | 4846 | 86.1 | 912 | |||||||||||

| 12.5 | 5336 | 88.5 | 982 | |||||||||||

| 16 | 6305 | 93 | 980 | 990 | 2000 | 2538 | ||||||||

| 19.5 | 8111 | 20.28 | 98.4 | 1040 | 1080 | 2500 | 3038 | |||||||

| 22.5 | 9416 | 102.3 | 1110 | 1100 | 3000 | 3538 | ||||||||

| 24 | 10065 | 104.2 | 1175 | 1100 | ||||||||||

|

20 |

9.5 | 6 9 12 15 18 |

A5 (2m) |

0.66/4 | 1420 | 4944 | P43 | 19.48 | 101.1 | 870 | 862 | 183 | 1800 | 2338 |

| 11 | 5441 | 105.3 | 912 | |||||||||||

| 12.5 | 5906 | 107.1 | 982 | |||||||||||

| 16 | 6756 | 111.6 | 1025 | 990 | 2000 | 2538 | ||||||||

| 19.5 | 8307 | 20.28 | 117.1 | 1135 | 1080 | 2500 | 3038 | |||||||

| 20 | 8500 | 118 | 1260 | 1100 | ||||||||||

| *This sample data is only for selection reference, | ||||||||||||||

| specific data please consult the technical department of YangyuMech. | ||||||||||||||

Components

-

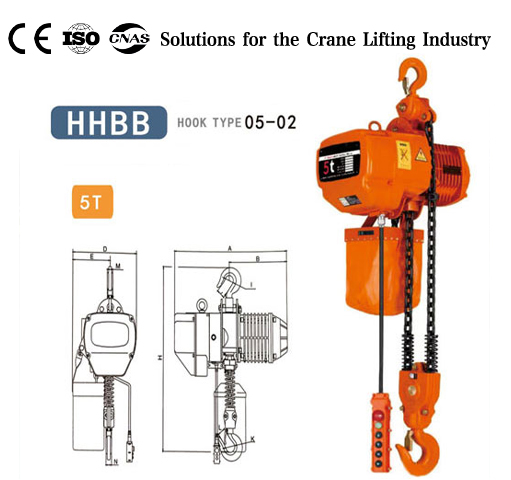

Electric hoist

The electric hoist will do dynamic and static load tests, as well as ascending and descending pressure tests. The baking paint process is used to enhance the adhesion of the paint film and improve the appearance quality. The assembly line ensures product quality.

-

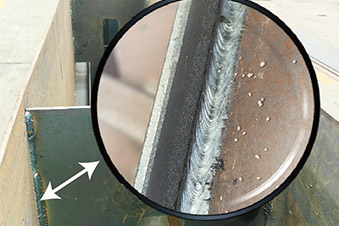

Main beam

1.Quality Assured

Multiple layers of control for each process, strict quality control, top-notchquality.

2.Fast Delivery

Physical factories, various specifications, sufficient inventory, fast delivery.

3.lmprove Work Efficiency

Flexible use, high work efficiency -

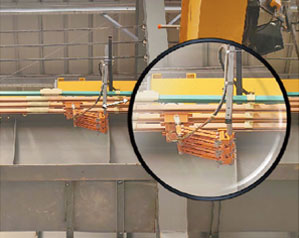

Wire Reel

Wire Reel store and release wound power cables used to run overhead cranes or hoists as needed. We offer both spring-driven and motorized Wire Reels. They can be used to provide electricity in tough and demanding applications, indoor and outdoor environments, explosion proof applications, monorails with lighter capacity hoists and below the hook devices.

-

Energy Supply Systems

Our crane energy supply systems allow you to maintain a superior organization scheme throughout all your work areas. These crane energy systems are ideal for every industry, be it shipbuilding, construction, or any other. As your crane energy company, you can be sure our products are reliable and robust, and they can stand up to some of the harshest conditions in the business.

-

Crane Cab

The crane cab is the workplace of the crane operator and it undertakes a crucial role. The design of the cab fully considers the comfort and safety of the operator. It has a good view so that the operator can clearly observe the surrounding environment and operating conditions.

-

Control model

Can use control handle with pendant line, wireless remote control, or cabin control.

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.