Home > Products > Gantry Crane > Single Girder Gantry Crane

Single Girder Gantry Crane

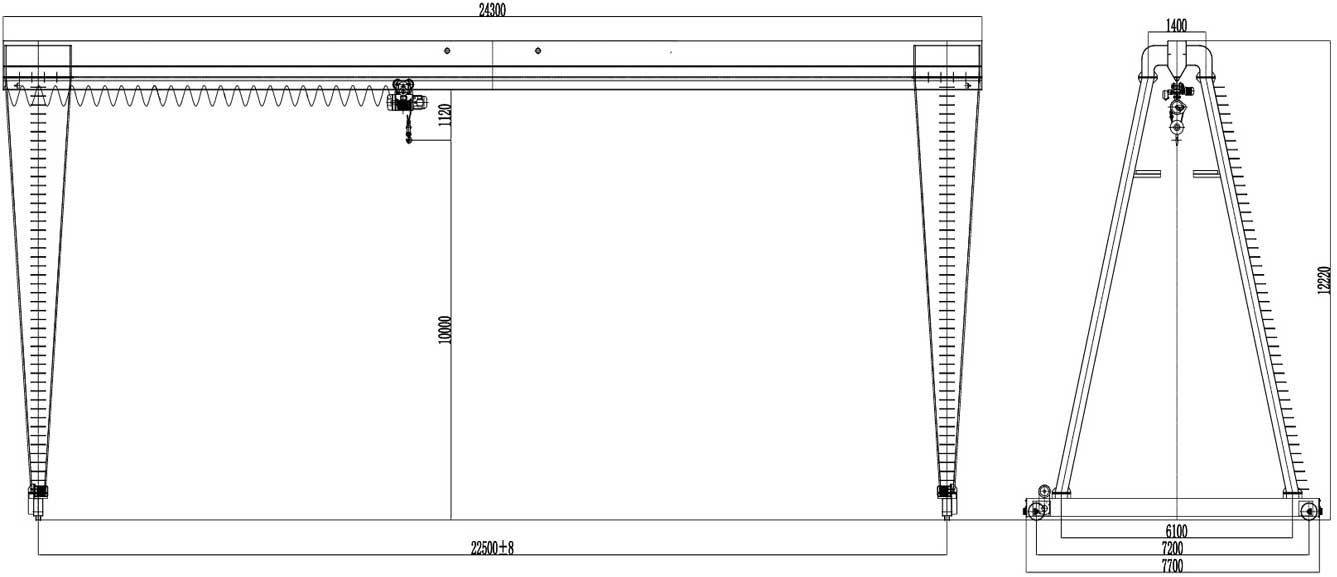

Single girder gantry crane is a common type gantry crane used indoor or outdoor, and it is also an ideal solution for light duty and medium duty material handling. Yangyumech can offer different type design of single girder gantry crane like box girder, truss girder, L shape girder, with low headroom hoist, standard room (monorail) hoist, to meet various applications with the features of compact design, light self-weight, low noisy, easy for installation and maintenance.

Capacity: 0.3t-36t; Span length: 4-35m

Lifting height: 6m, 9m, 12m, etc.

Raged voltage: 220V~690V, 50-60Hz, 3ph AC

Customized:YES

Description

Single Girder Gantry Crane

Work environment temperature: -25℃~+40℃, relative humidity ≤85%; Crane control mode: Pendantcontrol / Wireless remote control / Cabin control; Reference Price Range:$6000-30000/set

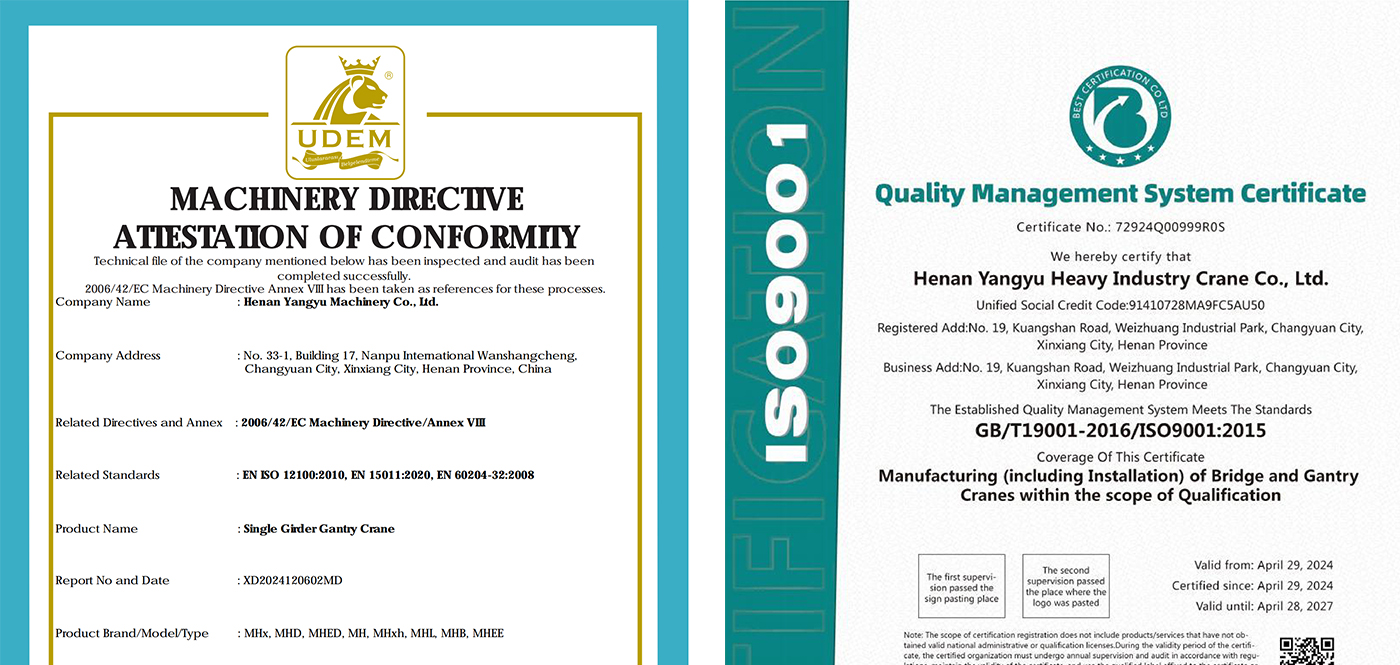

MH type electric hoist gantry crane is designed and manufactured in accordance with national and industry standards such as GB/T3811-2008 "Crane Design Specification" and JB/T5663-2008 "Electric Hoist Gantry Crane". It is one workshop lifting equipment, which uses CD MD electric wire rope hoist or electric chain hoist as the lifting mechanism. It can be used indoors and outdoors, such as the docks, freight yards, warehouses, and construction sites. The single girder gantry crane is mainly composed of steel structure gantry, crane traveling mechanism, electric hoist, and electric control system.Normally, single girder gantry cranes are most widely used and often in open storage yard. Considered the high quality, we ensure the gantry cranes price we offer is not the lowest but the most reasonable.

Box-type gantry crane : The box-type gantry crane is a box-type structure with the main beam structure, which has the advantages of high speed and high efficiency.The fixed working environment of the site.

Rubber-tyred gantry crane : Product introduction: The tire traveling gantry crane is a kind of gantry crane that uses tires instead of steel wheels to travel on the basis of the box gantry crane. It has the advantages of high speed, high efficiency and no need to pave the subgrade.

Truss gantry crane: The truss gantry crane is a truss structure with the main beam structure . It has the advantages of advanced structure,reasonable mechanical performance, portability, high rigidity, simple operation, convenient use, safety and reliability, and convenient disassembly.

As one of the experienced gantry crane manufacturers, we can produce different specifications of the crane.

Features

Single Girder Gantry Crane

Follows the international design code, like FEM, CMAA, EN ISO.

Can equip with low headroom hoist or standard room hoist.

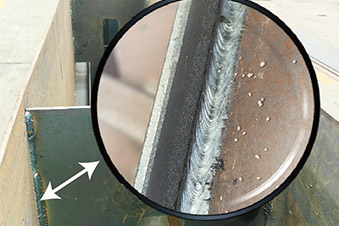

The girder is compact, low self-weight, and welded by S355 material, the welding specification follows ISO 15614, AWS D14.1, deflection can from 1/700 ~ 1/1000, MT or PT is requested for Fillet welding and UT is requested for joint welding.

The end carriage can be hollow shaft or open gear type design, the wheel is made by alloy steel with proper heat treatment.

Branding gear motor with IP55, F insulation class, IE3 Energy

efficiency, over-heat protection, manual release bar, and electro-magnetic brake feature. The motor is controlled by inverter for smooth running.

The control panel design follow IEC standard, and is installed inside IP55 enclosure with socket for easy Installation.

Double line Galvanized C track festoon system with flat cable, one line for hoist power and signal transmission, one line for the pendent control trolley movement.

SA2.5 Surface pre-treated by blasting according to ISO8501-1; C3-C5 painting system according to ISO 12944-5

Technical Data

Single Girder Gantry Crane

| Rated Load(Kg) | Working Level | Lifting Height | Lifting Speed | Iranversing speed | Traveling Speed | |

| FEM | ISO | M | M/Min | M/Min | M/Min | |

| 3000 | 1AM-4M | M3-M6 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 5000 | 1AM-4M | M3-M6 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 6300 | 1AM-4M | M3-M6 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 8000 | 1AM-4M | IM3-M6 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 10000 | 1AM-4M | IM3-M6 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 12500 | 1AM-3M | M3-M5 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 16000 | 1AM-3M | M3-M5 | 6/9/12/15/18 | 0.66/4 | 2~20 | 3~30 |

| 20000 | 1AM-3M | M3-M5 | 6/9/12/15/18 | 0.66/4 | 2~20 | 3~30 |

| 25000 | 1AM-3M | M3-M5 | 6/9/12/15/18 | 0.8/3.2 | 2~20 | 3~30 |

| 32000 | 1AM-3M | M3-M5 | 6/9/12/15/18 | 0.8/3.2 | 2~20 | 3~30 |

Components

-

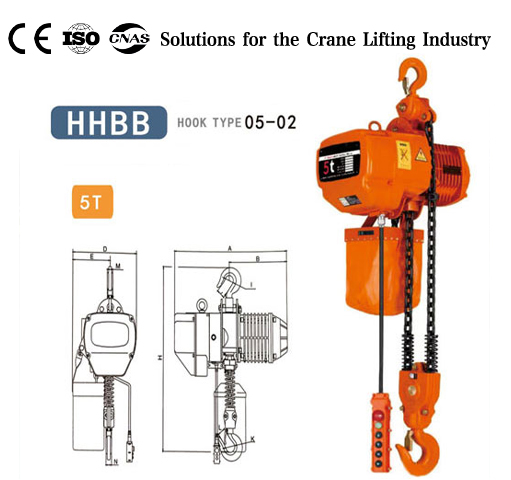

Electric hoist

The electric hoist will do dynamic and static load tests, as well as ascending and descending pressure tests. The baking paint process is used to enhance the adhesion of the paint film and improve the appearance quality. The assembly line ensures product quality.

-

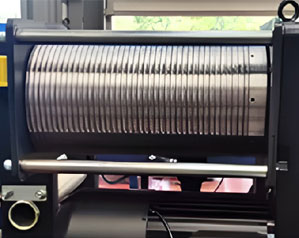

Reel

The reel is made of high-quality seamless pipes and processed by numeral control machine after the special finishing, the rope groove on reel works in coordination with the rope guide to efficiently prevent rope looseing and tangling.

-

Steel rope

Employ imported steel rope with high strength which has tensile strength of 2160 kN/mm2, with good safety performance and a long service life.

-

Ground beam

Mainly composed of cover plates, webs, ribs, flange supports and other parts. The production process is similar to that of the main beam and other box beams. The flange support is welded to the lower beam after the lower beam is made to ensure the level of the flange surface. When the lower beam and the leg are assembled, the flange on the flange made on the leg is welded to the leg.

-

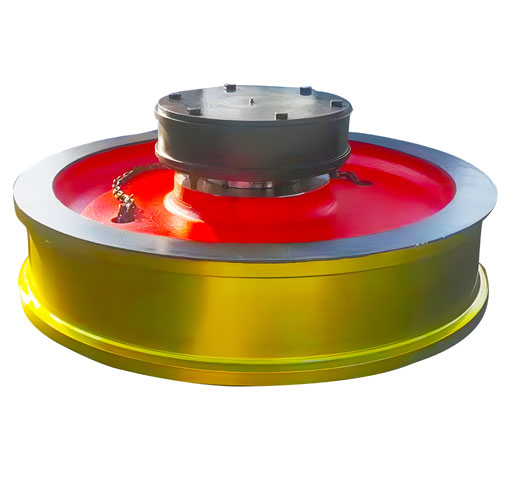

Wheel Set

The wheel set is a mechanical device consisting of a wheel and a shaft, a bearing and a bearing housing. The crane wheel set is generally used for the vehicle to support the crane and the load, and at the same time, the crane is allowed to perform the reciprocating running operation on the specified track.

-

Crane Cab

The crane cab is the workplace of the crane operator and it undertakes a crucial role. The design of the cab fully considers the comfort and safety of the operator. It has a good view so that the operator can clearly observe the surrounding environment and operating conditions.

-

Control model

Can use control handle with pendant line, wireless remote control, or cabin control.

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.