Home > Products > Port Crane > Ship To Shore Container Crane

Ship To Shore Container Crane

Ship-to-Shore (STS) container cranes are critical equipment in modern port operations, designed to efficiently load and unload containers from ships to the shore and vice versa. These cranes are a key component of container terminals, enabling the rapid movement of goods and ensuring the smooth operation of global supply chains.

In the modern port environment, reliability and productivity are the key parameters. Ship to shore container cranes (STS) achieve up to 99.5% availability during actual vessel operation.

Description

Ship-to-Shore (STS) Cranes are large dockside gantry cranes found at container terminals for loading and unloading intermodal containers. Generally classified by their lifting capacity and the size of the container ships they deal with, additional parameters indicate traveling and lifting speeds, the faster the better to minimize “deadtime” and be more efficient and profitable. Operators sit in a cabin suspended from the trolley, which runs along rails over the ship to lift the cargo. Once the spreader locks onto the container, the container is lifted, moved over the dock, and placed on the chassis either for direct shipment or to the storage yard.

Involve your team and build your specification

Does your terminal close at certain times or does it operate 24/7?

What are the peak performance and reliability that you require?

What type of terminal are you representing, brownfield or greenfield?

What are the physical dimensions of the container ships you currently serve?

Do you anticipate an increase in container throughput?

Are you investigating the possible benefits of automation?

Does your terminal have access to sufficient mains power for STS crane operation?

Yangyumech sales representative can help you develop in-depth answers via a thorough analysis of your case.

Types of Ship-to-Shore (STS) Cranes:

Standard Ship-to-Shore (STS) Cranes:

Designed for traditional container handling operations.

Suitable for Panamax and Post-Panamax vessels.

Super Post-Panamax Cranes:

Built for Ultra-Large Container Vessels (ULCVs) with greater outreach and lifting capacity.

Capable of handling 22+ rows of containers.

Automated Ship-to-Shore (STS) Cranes:

Fully or semi-automated for increased efficiency and reduced labor costs.

Often used in highly automated terminals like those in Rotterdam or Singapore.

Features

High-efficiency loading and unloading function?

Specially designed for the front of container terminal, it can accurately and quickly load and unload containers between ships. It reduces the docking time of ships in harbor and improve the efficiency of harbor cargo throughput.

Automation and Technology:

Advanced automation systems for precise container handling, including remote control and semi-autonomous operation.

Integration with Terminal Operating Systems (TOS) for real-time data exchange and optimized workflow.

Energy Efficiency:

Equipped with regenerative power systems to reduce energy consumption during lowering and braking operations.

Use of variable frequency drives (VFDs) for smoother and more efficient motor control.

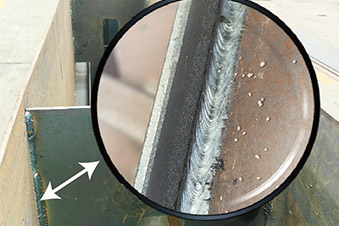

Durability and Reliability:

Built to withstand harsh marine environments, including saltwater corrosion and extreme weather conditions.

High-quality materials and components ensure long service life with minimal downtime.

Safety Features:

Comprehensive safety systems, including anti-collision, overload protection, and wind-speed monitoring.

Ergonomic operator cabins with advanced visibility and control systems.

Technical Data

| Main Technical Parameters | |||||||||||

| Basic Parameters | Rated Lifting Capacity | Under Spreader | 35 | 41 | 51 | 65 | t | ||||

| Under Hook | 45 | 50 | 61 | 75 | t | ||||||

| Lifting Height | Above Rail | 37 | 25 | 50 | 35 | 58 | 40 | 62 | 42 | m | |

| Below Rail | 12 | 15 | 18 | 20 | m | ||||||

| Front Outreach | 30 | 45 | 51 | 65 | m | ||||||

| Rear Outreach | 10 | 15 | 15 | 25 | m | ||||||

| Rail Gauge | 16 | 16/22 | 30.48 | 30.48 | m | ||||||

| Total Trolley Travel Distance | 56 | 76/82 | 96.48 | 120.48 | m | ||||||

| Inside Clearance Between Legs | ≥17.5 | ≥17.5 | ≥18.5 | ≥18.5 | m | ||||||

| Clear Height of Middle Cross Beam | ≥13 | ≥13 | ≥13 | ≥13 | m | ||||||

| Distance Between Gantry Bumpers | ≤27 | ≤27 | ≤27 | ≤27 | m | ||||||

| Speed Parameters | Lifting Speed | Full Load | 50 | 60 | 75 | 90 | m/min | ||||

| No Load | 120 | 120 | 150 | 180 | m/min | ||||||

| Trolley Traveling Speed | 180 | 210 | 240 | 240 | m/min | ||||||

| GantryTraveling Speed | 45 | 45 | 45 | 45 | m/min | ||||||

| Boom Hoisting Time (One Way) | 5 | 5 | 5 | 5 | min | ||||||

Components

-

-

Electric Trolley

Hoist trolley usually installed on the heavy duty bridge crane or gantry crane as a lifting mechanism. It has a simple structure and light weight. It’s mainly used in general hoisting, loading and unloading operations in machinery manufacturing workshops, warehouses, assembly and hydro-power station maintenance.

-

Main beam

The main beam is the crane's main load-bearing component, and the running track for the electric hoist. It is a triangular beam is weld by a support frame(welded by angle steel and other section steel) and an I-beam. The two sides of the span are designed with saddles connected to the outriggers, and there are rectangular steel plate connecting flanges. There are buffers at both ends of the main beam to ensure the safe operation of the trolley on the main beam.

-

Steel Lifting Spreader Beam

Steel Lifting beam can be used to lift and move a wide range of industrial loads. The hooks on both ends can be adjusted to any location you want. Lifting beam is a good choice when the headroom is limited and restricts the use of overhead rigging in the application. Lifting beam is usually made from a beam and a single lifting point at the top with several lift points at the bottom.

-

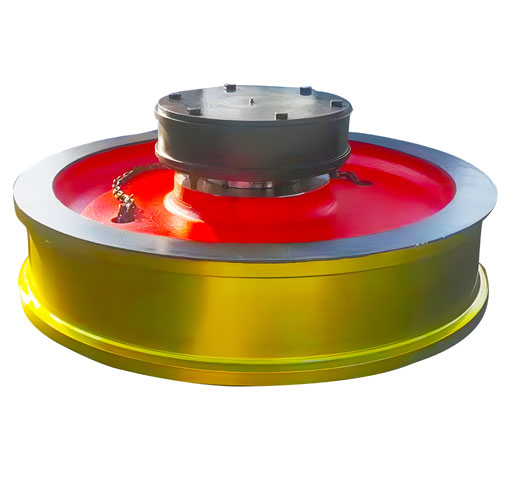

Wheel Set

The wheel set is a mechanical device consisting of a wheel and a shaft, a bearing and a bearing housing. The crane wheel set is generally used for the vehicle to support the crane and the load, and at the same time, the crane is allowed to perform the reciprocating running operation on the specified track.

-

Crane Cab

The crane cab is the workplace of the crane operator and it undertakes a crucial role. The design of the cab fully considers the comfort and safety of the operator. It has a good view so that the operator can clearly observe the surrounding environment and operating conditions.

-

Control model

Can use control handle with pendant line, wireless remote control, or cabin control.

-

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.