Home > Products > Gantry Crane > Rubber Tyred Gantry Crane / RTG container crane

Rubber Tyred Gantry Crane / RTG container crane

Rubber tyred gantry cranes (RTG container crane) are available with spans of between five and ten containers wide (plus a truck lane) and with hoisting heights from 1 over 3 to 1 over 6 containers high.

Yangyumech rubber tyred gantry cranes demonstrate their technological advantage through increased productivity and a proven low cost per box move. The Yangyumech high quality standard achieved, with ease of maintenance results in minimum downtime, increasing throughput per rubber tyred gantry crane unit.

Capacity: 5t-900t; Span: 5~50m

Description

The rubber tyred gantry crane has a rigid and stable steel structure allowing precise handling with smooth movements even at high speeds. Supplied with eight rope reeving anti-sway system and drive systems, the RTG delivers exceptional productivity and reliability in container stacking. Precise control using simultaneous drive motion removes the need for a headblock or side shift. Available in either eight or 16 wheel configuration with numerous productivity options from DGPS and auto steering to stack profiling and automation.

The rubber tyred gantry crane offers high efficiency, flexibility, and mobility, which can be used in various industries and applications. Such as casting yards, bridge erection, external logistics, and storage, wind energy, power plants, steel mills, ports, etc. Yangyumech offers different types of industrial rubber tyred gantry crane for sale: single girder, double girder, and A-frame, which can meet any working conditions. Tell us your specific requirements and our professional engineer team will provide you a customized solution.

Features

Yangyumech's unique 8 rope reeving anti-sway system

Simultaneous drive motion

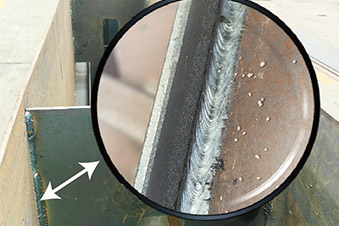

Rigid robust structure

Direct driven travel systems

1 gantry drive per corner

Designed and built drive systems

Reputable China suppliers

Hoist ropes reeved directly to the telescopic spreader

Gantry align steering

Technical Data

| Item | Data |

| Capacity | 900T |

| Span | 5~50M |

| Lifting Height | 6~21M |

| Lifting Speed | 6~46M/Min |

| Working Duty | A6~A8 |

| Cross Travelling Speed | 45~70M/Min |

| Long Travelling Speed | 45~100M/Min |

Advantages and Benefits:

Exceptional anti-sway performance; Accurate spreader positioning - no headblock - better visibility;

No headblock, reduced tare weight; Increased productivity compared with alternative designs;

Smooth gantry operation; Improved performance where high winds prevail;

Optimum design for automation; Low maintenance and spare part costs;

Lower energy and fuel costs; Spreader sideshift eliminated due to simultaneous motion;

In-house expertise and excellent after sales service

Components

-

-

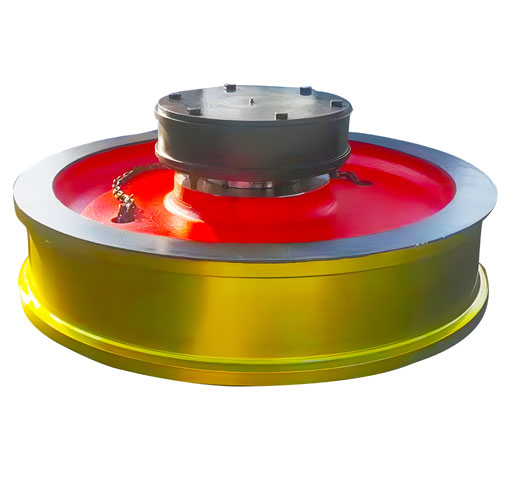

Wheel Set

The wheel set is a mechanical device consisting of a wheel and a shaft, a bearing and a bearing housing. The crane wheel set is generally used for the vehicle to support the crane and the load, and at the same time, the crane is allowed to perform the reciprocating running operation on the specified track.

-

Crane Cab

The crane cab is the workplace of the crane operator and it undertakes a crucial role. The design of the cab fully considers the comfort and safety of the operator. It has a good view so that the operator can clearly observe the surrounding environment and operating conditions.

-

Control model

Can use control handle with pendant line, wireless remote control, or cabin control.

-

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.