Home > Products > Gantry Crane > Rail mounted container gantry cranes(RMG)

Rail mounted container gantry cranes(RMG)

Rail-Mounted Gantry (RMG) crane is the product of decades of crane design experience and knowledge. It incorporates a host of technological innovations, including the smarter cabin with video and monitoring technology that provides superb visibility to container handling operations. We can tailor your RMG for your specific operation. Rail mounted gantry cranes (RMGs) are manufactured to individual customer needs in a variety of different stacking heights and spans. Supplied with Yangyumech rail mounted gantry crane delivers exceptional productivity and reliability.

Description

Rail Mounted Gantry (RMG) cranes are essential in container handling operations, particularly in ports and large distribution centers. Their design and functionality make them crucial for managing container storage and retrieval efficiently.

Available with stacking heights of up to seven containers high, with custom spans in excess of 62 metres and outreaches up to 12 metres, designed for manual, semi-automatic or automatic operation. Yangyu anti-sway system and simultaneous motion of all drives leads to increased productivity.

Rail Mounted Gantry cranes are integral to container handling in ports and distribution centers. By understanding their operational workflow and employing strategies to enhance efficiency, organizations can achieve greater productivity, reduce costs, and ensure smooth operations. Regular maintenance, technological upgrades, optimized procedures, safety measures, and efficient mobility are all crucial elements in maximizing the performance of RMG cranes. Investing in these areas will not only extend the equipment’s lifespan but also contribute to overall operational excellence.

Features

Exceptional anti-sway performance

Accurate spreader positioning - no headblock - better visibility

No headblock, reduced tare weight

Increased productivity compared with alternative designs

Low maintenance and spare part costs

Smooth gantry operation

Improved performance where high in-service winds prevail

Optimum design for automation

In-house expertise and excellent aftersales service

Lower energy costs

Spreader side shift eliminated due to simultaneous motion

Technical Data

|

Model |

LJ35/40-23 |

Light Type LJ40-23 |

|

Lifting capacity (without spreader) (t) |

35,40 |

40 |

|

Work level |

A7,A8 |

A6,A7 |

|

Span (m) |

23.47 |

23.47 |

|

Lifting Height (m) |

12.2~17.8 |

16.5 |

|

Stack layer |

3/4~5/6 |

5/6 |

|

Container size |

20',40',45' |

20',40',45' |

|

Spreader rotation angle |

±5° |

±5° |

|

Lifting (m/min) |

13/26,23/52 |

12/18,18/28 |

|

Trolley travelling (m/min) |

50,70 |

24 |

|

Crane travelling (m/min) |

Full load-90, no load-130 |

Full load-20, no load-40 |

Components

-

-

Electric Trolley

Hoist trolley usually installed on the heavy duty bridge crane or gantry crane as a lifting mechanism. It has a simple structure and light weight. It’s mainly used in general hoisting, loading and unloading operations in machinery manufacturing workshops, warehouses, assembly and hydro-power station maintenance.

-

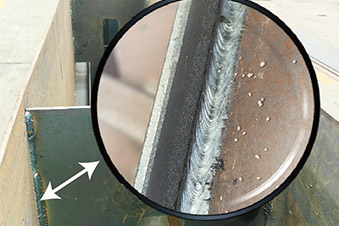

Main beam

The main beam is the crane's main load-bearing component, and the running track for the electric hoist. It is a triangular beam is weld by a support frame(welded by angle steel and other section steel) and an I-beam. The two sides of the span are designed with saddles connected to the outriggers, and there are rectangular steel plate connecting flanges. There are buffers at both ends of the main beam to ensure the safe operation of the trolley on the main beam.

-

Steel Lifting Spreader Beam

Steel Lifting beam can be used to lift and move a wide range of industrial loads. The hooks on both ends can be adjusted to any location you want. Lifting beam is a good choice when the headroom is limited and restricts the use of overhead rigging in the application. Lifting beam is usually made from a beam and a single lifting point at the top with several lift points at the bottom.

-

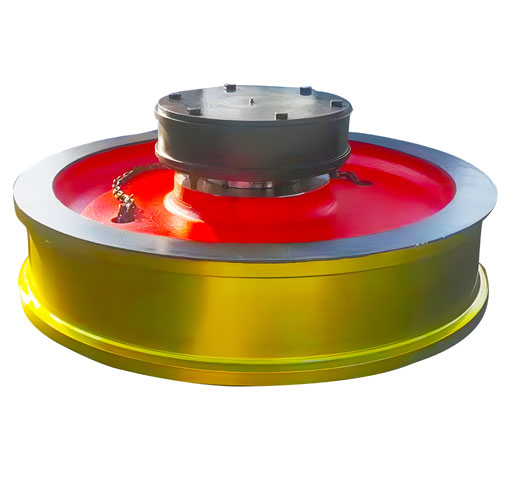

Wheel Set

The wheel set is a mechanical device consisting of a wheel and a shaft, a bearing and a bearing housing. The crane wheel set is generally used for the vehicle to support the crane and the load, and at the same time, the crane is allowed to perform the reciprocating running operation on the specified track.

-

Crane Cab

The crane cab is the workplace of the crane operator and it undertakes a crucial role. The design of the cab fully considers the comfort and safety of the operator. It has a good view so that the operator can clearly observe the surrounding environment and operating conditions.

-

Control model

Can use control handle with pendant line, wireless remote control, or cabin control.

-

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.