Home > Products > Gantry Crane > Mobile Gantry Crane(portable/ movable)

Mobile Gantry Crane(portable/ movable)

The Yangyumech portable gantry crane can be divided into two types: manual gantry crane and electric gantry crane. If the fixed crane is too complicated for you or cannot be installed, then our N-KBK gantry crane will be your most ideal solution. They can run on a solid and flat ground and can be moved easily in any direction. It will be an ideal choice for various loading and unloading operations in your workshop, as well as maintenance and repair work.

Capacity: 5T-10T

Customized:YES

Description

Manual gantry crane: The NL-PC hand-push gantry crane is used where there are no other lifting equipment. It is a simple device with a lightweight design and can be moved easily in any direction. It can be disassembled and reassembled easily. Its main features are as follows:

Maximum lifting capacity 2000kg

Maximum span 7m (<125kg)

Multiple lifting height options

The crossbeam and outriggers can be disassembled for convenient transportation

Both the trolley and the trolley carriage need to be pushed by hand

In order to ensure its correct function and safety without tilting, it requires a smooth and level ground

With 4 casters with brakes

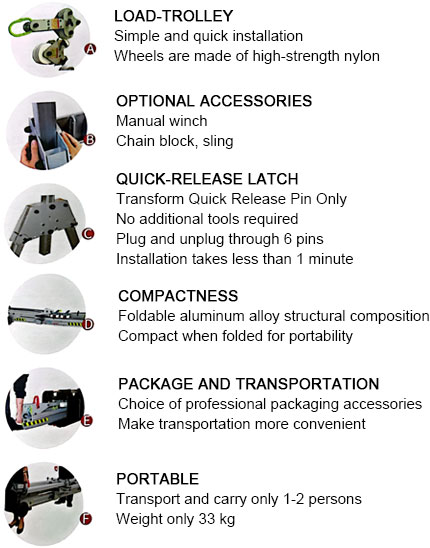

Detachable Gantry Crane: The Yangyumech aluminum alloy gantry crane is a new type of small-sized aluminum alloy gantry crane for lifting developed to meet the daily production needs of medium and small factories, storefronts, and outdoor lights, such as transporting equipment, loading and unloading goods in warehouses, hoisting and maintaining heavy equipment, and transporting materials. It is suitable for manufacturing molds, auto repair factories, mines, construction sites and other occasions that require hoisting. The greatest advantage of this aluminum alloy gantry crane is its all-round mobility, quick disassembly and installation, small floor space, and it can be transferred to another site for installation and use with a mini car. The width and height can be adjusted hierarchically. The steel structure is reasonably designed and can bear the weight from 100-5000KG.

The paint of the aluminum alloy gantry crane is suitable for the installation, transportation and debugging of workshop equipment. The aluminum alloy gantry crane mainly has two specifications:

First, the gantry crane that can move in all directions on the ground. The load-bearing wheels with brakes can move on the ground and are suitable for hoisting items on the ground;

Second, it is fixedly installed on the floor or beam with rails, and realizes the mechanization of lifting through electric or manual hoists. It can reduce manpower, lower production and operation costs, and improve work efficiency. Noell Cranes can customize different products according to the on-site situation of customers.

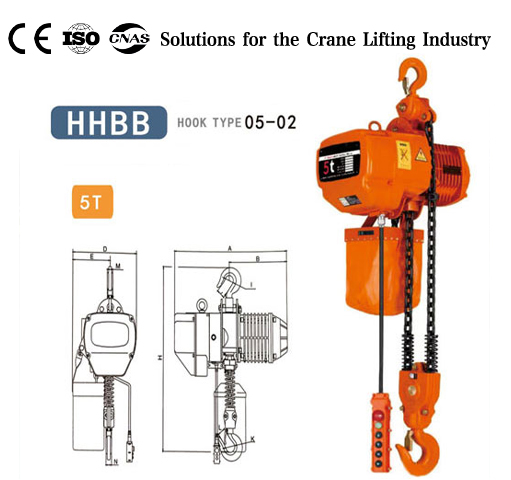

The hoisting hoist of the aluminum alloy gantry crane can be selected as a manual hoist or an electric hoist. The product is highly practical.

Convenient transportation and assembly do not affect the strength. It is safe to use (the lifting capacity can reach 5000kg). Corresponding sizes and configurations can be customized according to the usage environment.

Each portable gantry crane includes:

2 pieces of A-type outrigger structures (customizable)

Trolley - extremely safe fully enclosed type

The length of the girder can reach 9000mm (depending on the lifting capacity)

Features

Swivel castor wheel with brakes

Overload protective device

Limit switch to prevent overhoisting and overlowering

Safety catch on the hook

IP 54 protection for all motors

Push button pendant complete with control cable

Flexible flat festoon cable system for cross travel power supply

Technical Data

| Lifting capacity | Tyoe | Maximum Hook Height | Height increment | Minimum hook height | maximum height of top beam | Overall maximum height | Overall minimum height | Weight | Self-weight | Caster size |

| 500 | S | 2355 | 5×150 | 1605 | 2675 | 2757 | 2007 | 1212 | 33 | 85×150 |

| M | 2851 | 5×150 | 2101 | 3171 | 3253 | 2503 | 1429 | 40 | 85×150 | |

| | | 3188 | 5×200 | 2188 | 3499 | 3581 | 2581 | 1726 | 46 | 85×200 | |

| T | 4079 | 6×200 | 2879 | 4399 | 4481 | 3281 | 2011 | 51 | 85×200 | |

| 1000 | S | 2355 | 5×150 | 1605 | 2675 | 2757 | 2007 | 1212 | 33 | 85×150 |

| M | 2851 | 5×150 | 2101 | 3171 | 3253 | 2503 | 1429 | 40 | 85×150 | |

| | | 3188 | 5×200 | 2188 | 3499 | 3581 | 2581 | 1726 | 46 | 85×200 | |

| T | 4079 | 6×200 | 2879 | 4399 | 4481 | 3281 | 2011 | 51 | 85×200 | |

| 2000 | S | 2355 | 5×150 | 1605 | 2675 | 2757 | 2007 | 1212 | 33 | 85×150 |

| M | 2851 | 5×150 | 2101 | 3171 | 3253 | 2503 | 1429 | 40 | 85×150 | |

| | | 3188 | 5×200 | 2188 | 3499 | 3581 | 2581 | 1726 | 46 | 85×200 | |

| T | 4079 | 6×200 | 2879 | 4399 | 4481 | 3281 | 2011 | 51 | 85×200 | |

| 3000 | S | 2410 | 5×150 | 1660 | 2730 | 2812 | 2062 | 1212 | 55 | 85×150 |

| M | 2906 | 5×150 | 2155 | 3226 | 3380 | 2558 | 1429 | 60 | 85×150 | |

| | | 3188 | 5×200 | 2188 | 3499 | 3581 | 2581 | 1726 | 76 | 85×200 | |

| T | 4079 | 6×200 | 2879 | 4399 | 4481 | 3281 | 2011 | 82 | 85×200 | |

| 5000 | | | 3188 | 5×200 | 2181 | 3592 | 3717 | 2717 | 1736 | 97 | 85×200 |

| T | 4079 | 6×200 | 2849 | 4487 | 4612 | 3412 | 2021 | 106 | 85×200 |

Components

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.