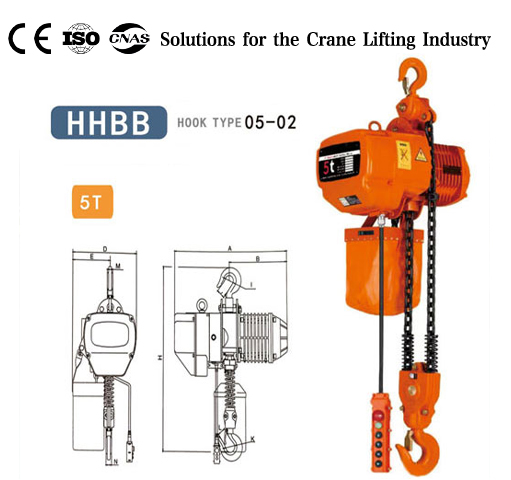

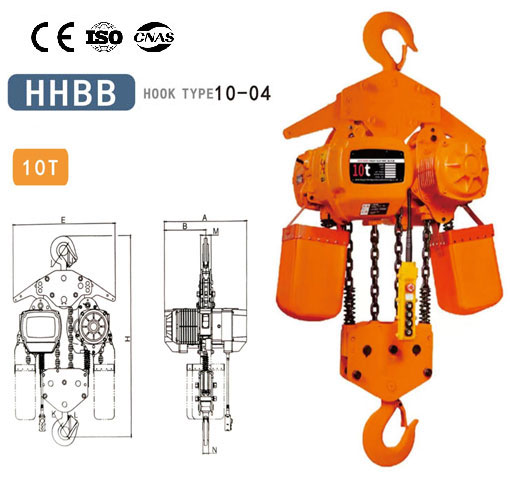

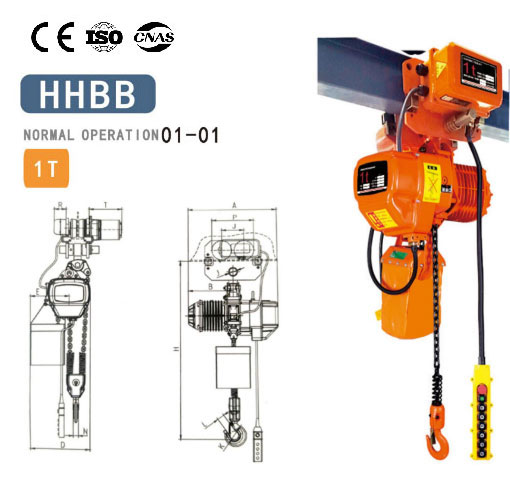

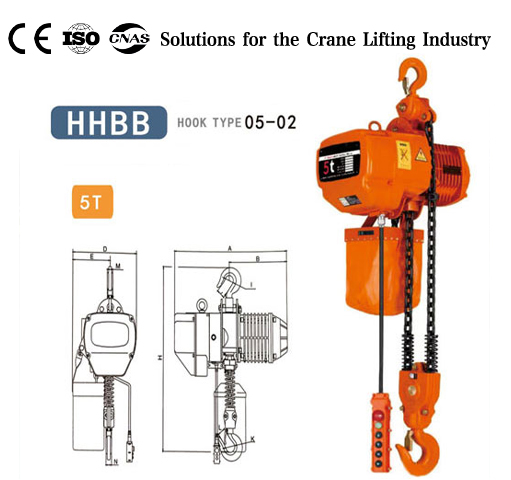

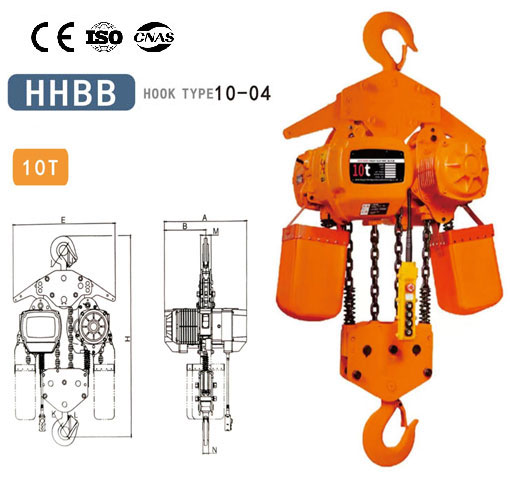

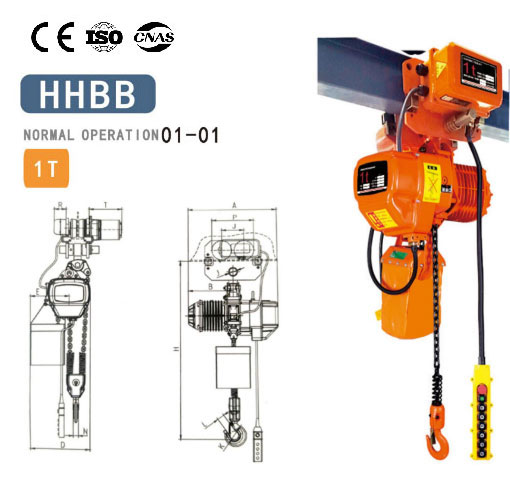

Chain Hoist, Electric Chain Hoist

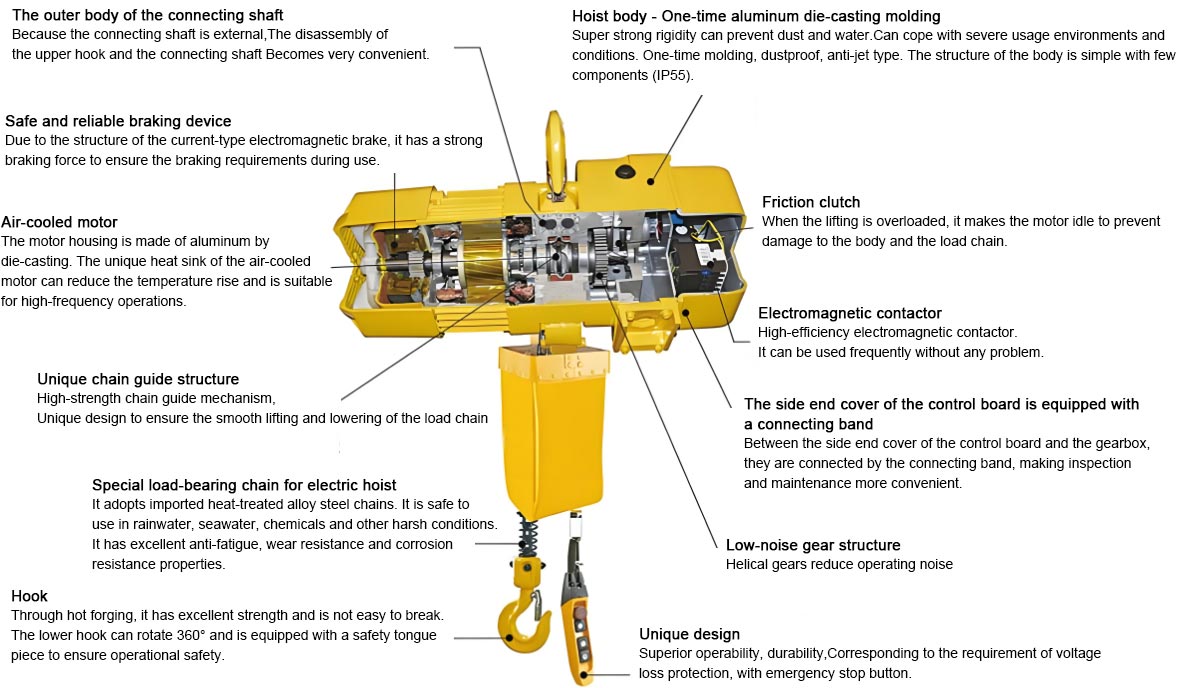

Light aluminum alloy shell shall be adopted, which is light but hard ane fit for the use in the terrible work environment with a high heat dissipation rate and all tightness design. Inverse phase sequence protecting device: It is the special electrical installation which controls the circuit not to work in case of wiring error in power supply. 24V/36V device: It is used to prohibit the emergencies from occurring in case of the leakage in the switch.

Lifting Capacity: 0.3-32t

Customized:YES

Description

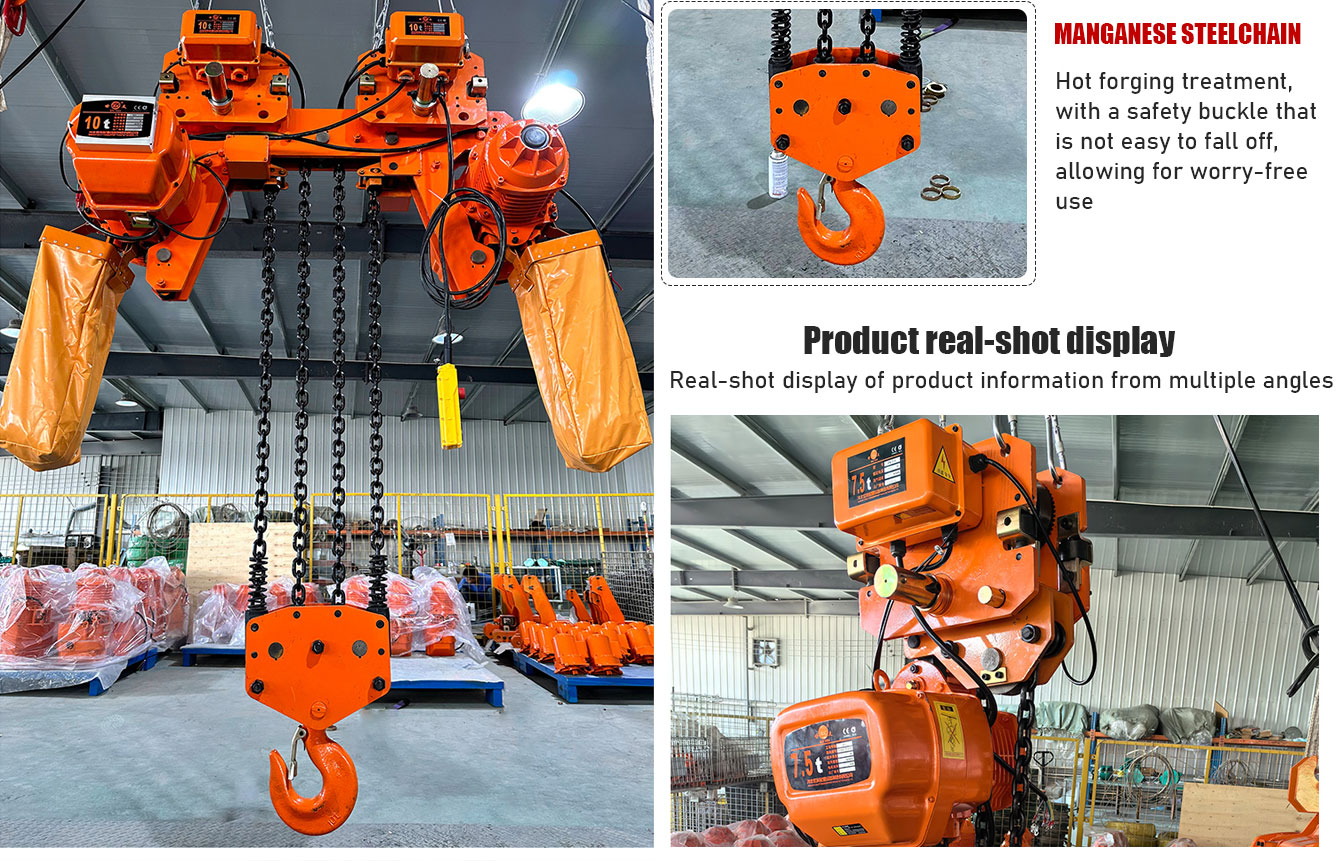

Yangyumech series chain hoist shell is light and solid, with good heat dissipation performance, and can be used under relatively bad working conditions. The motor is low noise, safe and reliable. Reverse phase protection device ensures safe use. The chain is made of imported FEC80 super heat treated alloy steel chain. The hook is hot forged with high strength and is not easy to break. With kbk flexible crane, it is very suitable for use on various assembly lines.

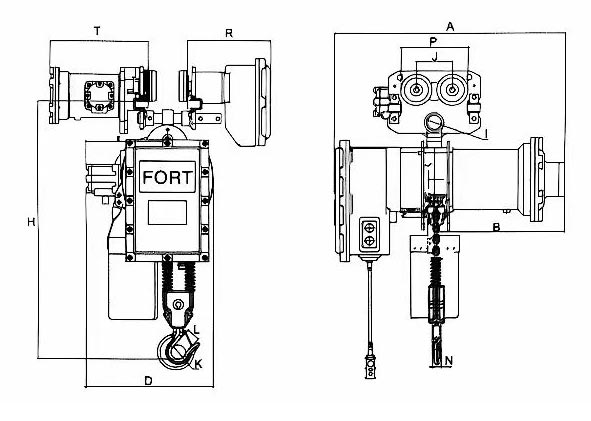

Low Clearance Electric Chain Hoist

The optimal clearance height can increase the lifting height by 200-500mm compared to ordinary CD hoists.

Excellent three in one transmission technology, the lifting reducer is made of high-quality alloy steel, with three-stage reduction, smooth operation, long service life, and reliable performance, avoiding many drawbacks of long-distance transmission of the intermediate shaft of the CD hoist.

The motor is a specially designed new type of self cooling cone motor, with an outer shell made of aluminum alloy material with good heat dissipation performance. The insulation level of the motor is F level, and the protection level is IP54, which is one level higher than ordinary motors.

According to user requirements, it can achieve various functions such as hoist operation, single and double speed lifting or variable frequency stepless speed control, remote control operation, overload protection, motor overheating protection, etc. The entire structure is easy to disassemble and install, with convenient maintenance and good maintainability.

Anti-explosion Electric Chain Hoist

Explosion-proof electric chain hoist is applicable to the combustible gas, steam and air that are easy to explode Flammable and explosive workplace with sparks (such as coal mine, pharmaceutical factory, chemical factory, etc.). The explosion-proof grade is DIIBT4 and DIICT4 respectively,The exposed explosion-proof parts of the hoist are made of special non-sparking materials. The motor, electric appliance, sports wheel, guideRope device, hook, operating handle, etc. are explosion-proof, with safe and reliable explosion-proof performance. The explosian-proof electric hoist produced by our factory has passed The quality supervision and inspection center conducted explosion-proof performance test and issued explosion-proof certificate. Applicable to indoor temperature of -25 C-+40°Cuse; Protective devices shall be added when outdoor use is required under special circumstances.

Yangyumech explosion-proof chain electric hoist can be installed on l-beam track with sports car for straight or curve operation. It can be used together with explosion-proof single-beam suspension crane or explosion-proof single-beam and double-beam bridge crane according to different requirements. Also it can be fixed on the bracket for direct use.

Features

The European electric chain hoist can be easily installed on the track of KBK standard components.

Simple testing: All electrical connections are plug-in plug and play universal suspension mechanisms, which can be used on KBK standard tracks and quickly linked to small cars.

User-friendly design: The length of the control cable can be adjusted, and the flashlight is always in the most suitable position. The humanized design of the flashlight door provides a comfortable grip and eliminates operational fatigue.

Unified maintenance and inspection of the rear cover: Can be used for electrical connections, height adjustment of flashlights, and chain lubrication. No need to disassemble other components, quickly replace the lifting sprocket, reduce downtime

Technical Data

| Model | Load capacity (KG) |

Lifting speed (m/min) |

Motor power (Kw) |

Motor speed (r/min) |

Working voltage (V) |

Control voltage (V) |

Working level (FEM/ISO) |

||||||||

| BMS0.125-01M | 125 | 8/2 | 0.75/0.2 | 2880/720 | 220-460 | 24 | 2M/M5 | ||||||||

| BMS0.125-01M | 125 | 13/3.2 | 0.75/0.2 | 2880/720 | 220-460 | 24 | 2M/M5 | ||||||||

| BMS0.25-01M | 250 | 8/2 | 0.75/0.2 | 2880/720 | 220-460 | 24 | 2M/M5 | ||||||||

| BMS0.5-01M | 500 | 8/2 | 0.75/0.2 | 2880/720 | 220-460 | 24 | 2M/M5 | ||||||||

| BMS0.5-01M | 500 | 12/3 | 1.5/0.37 | 2880/720 220-460 | 24 | 2M/M5 | |||||||||

| BMS0.5-02N | 500 | 4/1 | 0.75/0.2 | 2880/720 220-460 | 24 | 2M/M5 | |||||||||

| BMS01-01M | 1000 | 8/2 | 1.5/0.37 | 2880/720 220-460 | 24 2M/M5 | ||||||||||

| BMS01-02M | 1000 | 4/1 | 0.75/0.2 | 2880/720 220-460 | 24 2M/M5 | ||||||||||

| BMS02-02M | 2000 | 4/1 | 1.5/0.37 | 2880/720 220-460 24 2M/M5 | |||||||||||

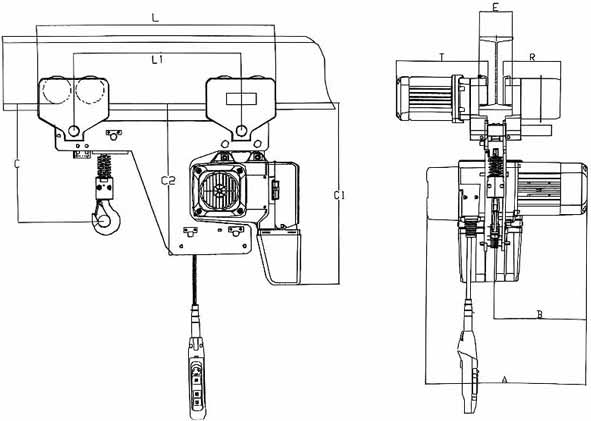

| Model | L | L1 | C | C1 | C2 | A | B | T | E | R | |||||

| BMS0.125-01M | 645 | 454 | 330 | 510 | 415 | 464 | 267 | 260 | 100-200 164 | ||||||

| BMS0.125-01M | 645 | 454 | 330 | 510 | 415 | 464 | 267 | 260 | 100-200 | 164 | |||||

| BMS0.25-01M | 645 | 454 | 330 | 510 | 415 | 464 | 267 | 260 | 100-200 | 164 | |||||

| BMS0.5-01M | 645 | 454 | 330 | 510 | 415 | 464 | 267 | 260 | 100-200 | 164 | |||||

| BMS0.5-02M | 645 | 454 | 410 | 510 | 415 | 464 | 267 | 260 | 100-200 | 164 | |||||

| BMS01-01M | 900 | 548 | 350 | 680 | 630 | 548 | 305 | 290 | 100-200 | 190 | |||||

| BMS01-02M | 645 | 454 | 410 | 510 | 415 | 464 | 267 | 260 | 100-200 | 164 | |||||

| BMS02-02M | 900 | 548 | 510 | 690 | 630 | 548 | 305 | 290 | 100-200 | 190 | |||||

Components

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.