KBK Suspension Monorail Crane

The KBK light-load lifting system made of rigid or aluminum profiles has changed the traditional industrial field's understanding of cranes, making the crane design lighter, more convenient to assemble, and more ergonomic to use, revolutionizing work efficiency and providing benefits to the industrial field. Provides more cost-effective options

Rated load(ton): 0.5/1/2/5

Motion Type: Electric control type

Description

KBK Customized Solutions

The KBK light crane system has been interviewed for over 50 years, and today, this product has become a global market leader in the field of light crane systems. Our KBK lightweight crane system can accurately, quickly, and efficiently meet your specific application requirements. Our modular system components can travel personalized suspension monorail systems, suspension cranes, column and wall cantilever suspension solutions through different combinations, thanks to their high flexibility, KBK Equipment Technology is easily integrated into all production infrastructures and can be modified as needed at any time.

Features

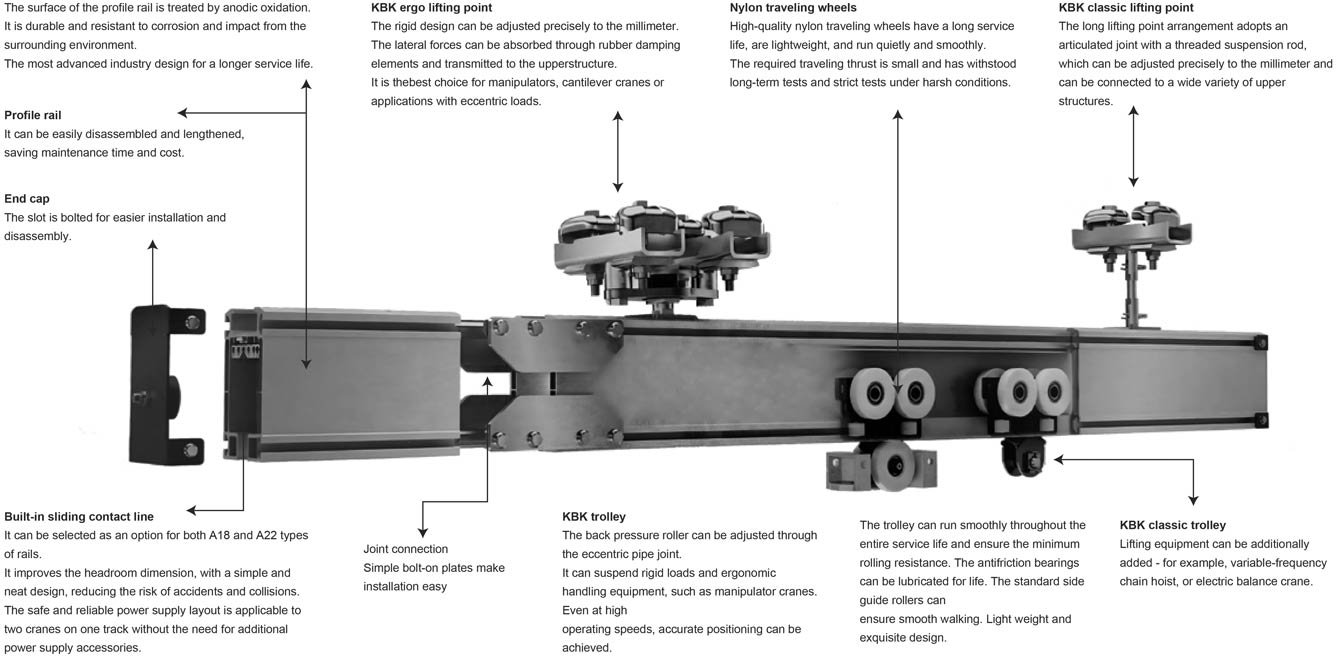

Special cold-rolled carbon steel material, made of Q235B, with more uniform material, more stable performance, better rigidity and fewer defects

Light weight, good rigidity, smooth surface. When welding the entire piece, it is controlled by a computer program in one go. The special guiding surface and slightly inclined contact surface inside the track ensure the smoothness of the car's movement

The maximum deflection allowed by the material under rated load shall not exceed 1/800 of the span, ensuring permanent deformation under normal use

Electrostatic spraying on the inner and outer surfaces, with a paint layer thickness of up to 100 microns, strong adhesion, corrosion resistance and durability

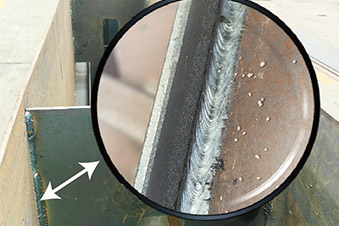

The track is completed by a welding robot in one go, ensuring uniform and high-quality welding points and even heating of the track with minimal deformation. After welding, special equipment is used to eliminate welding stress and deformation, completely ensuring that the steel rail does not deform

The straightness of the shaped rail is less than 0.75mm/m

The track within the medium and low load range adopts an internal operation design to protect the car and the built-in (enclosed) sliding contact line

Technical Data

| Load capacity:kg | ||||||||||

| Type | Specification | 125 | 250 | 500 | 1000 | 1600 | 2000 | 2500 | 3200 | |

| I 250 Ⅱ-L 370 |

Span | 3.8 | 2.6 | |||||||

| The length of the main girder | 7.9 | 5.9 | 3.7 | 2.7 | ||||||

| Ⅱ 400 II-H 413 |

Span | 8.0 | 5.7 | 3.2 | ||||||

| The length of the main girder | 10.5 | 9.2 | 6.7 | |||||||

| Ⅲ 446 | Span | 3.7 | 3.0 | 2.3 | 1.9 | |||||

Components

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.