Hand Chain Hoist

Smooth, non-jamming chain, Portable and durable

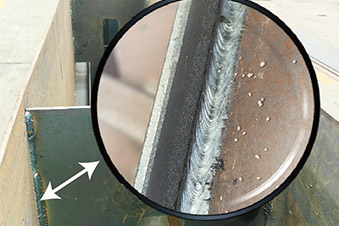

Sturdy durable

Duration of use longer

Smooth guide pulley

Lifting Capacity: 0.5~46t; Customized:YES

Description

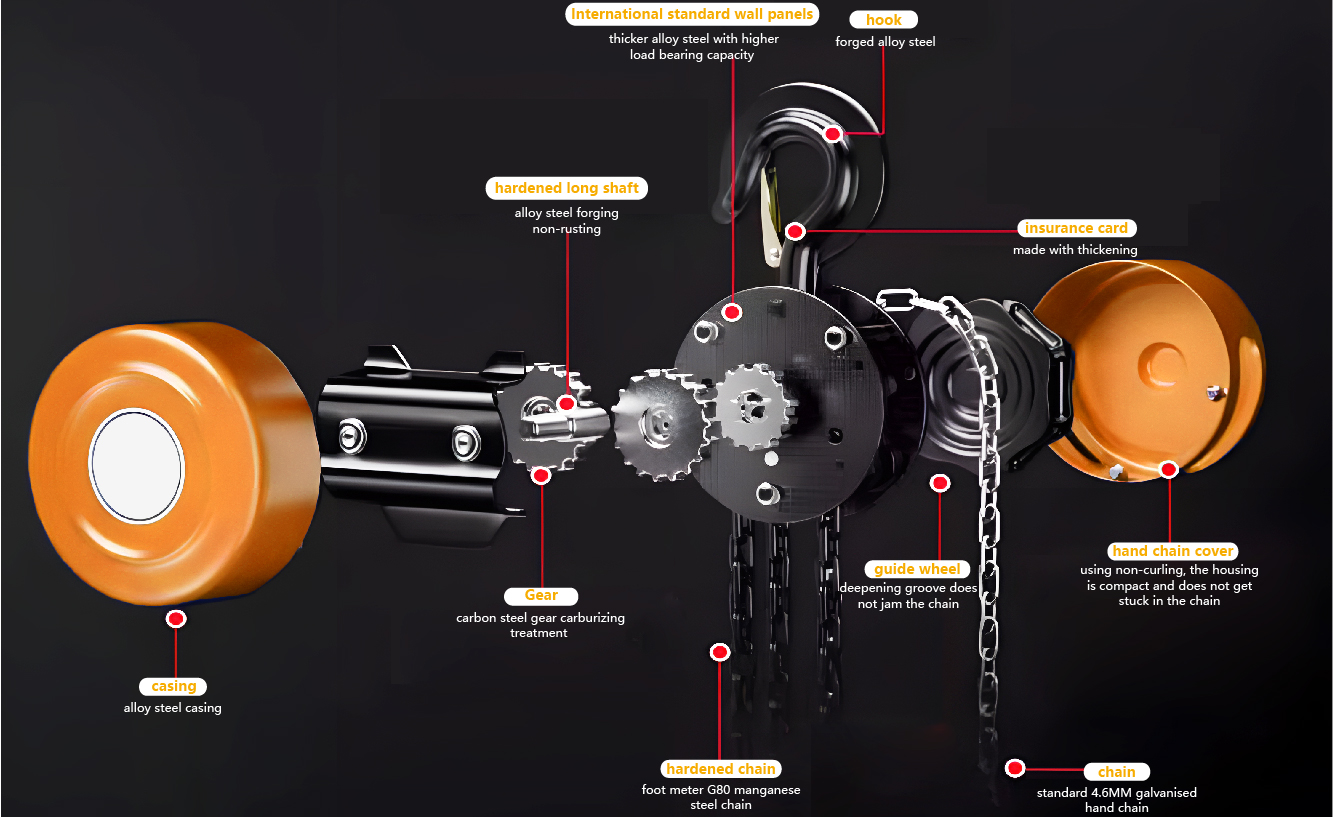

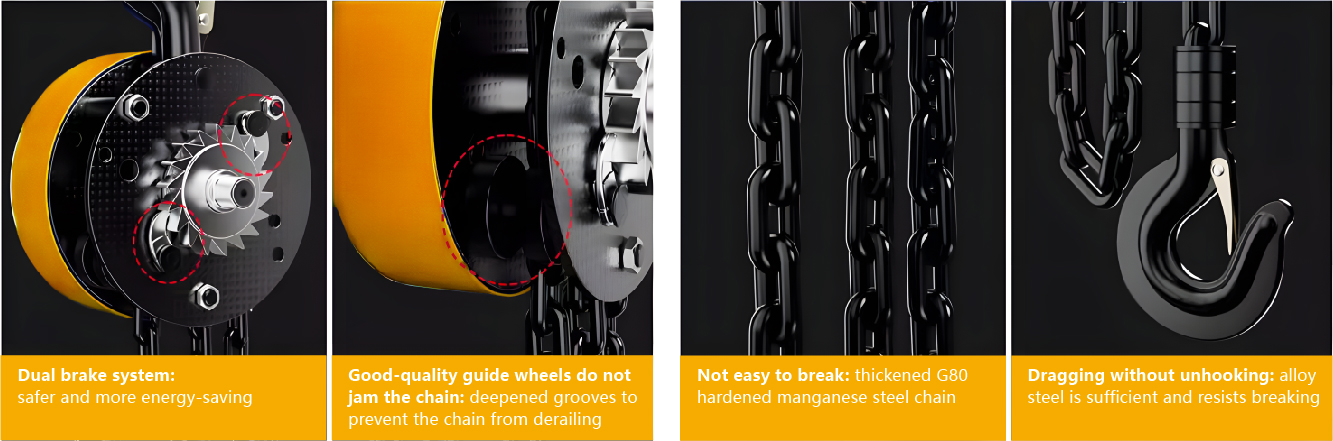

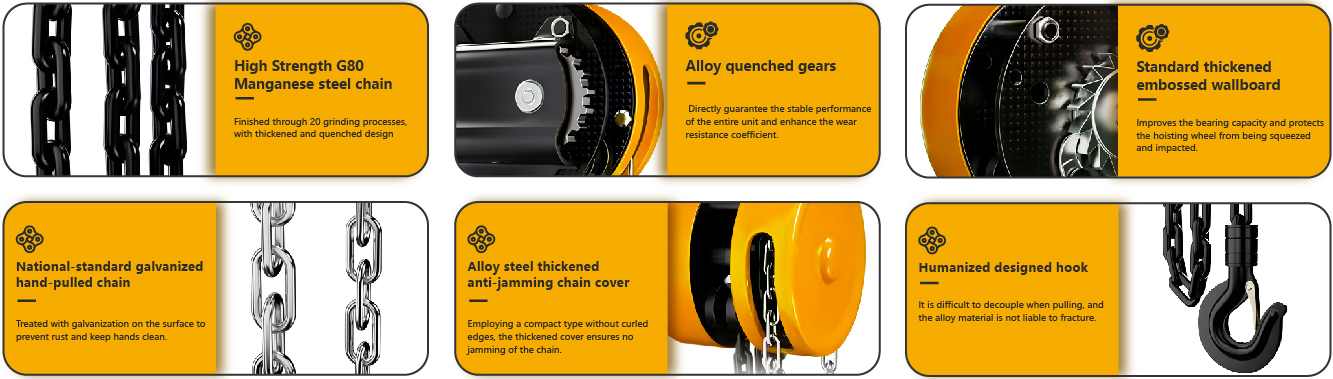

It is suitable for short distance lifting of small equipment and goods, with a lifting capacity generally not exceeding 10T and a maximum of 20T, and a lifting height generally not exceeding 6m. The shell material of the chain hoist is high-quality alloy steel, which is sturdy, wear-resistant, and has high safety performance. When lifting a heavy object with a chain hoist, pull the manual chain and handwheel clockwise to rotate. When lowering, pull the manual zipper counterclockwise to separate the brake seat from the brake pad. The ratchet is stationary under the action of the pawl, and the five tooth long shaft drives the lifting sprocket to run in the opposite direction, thus smoothly lowering the heavy object. Hand chain hoists generally use a ratchet friction plate type one-way brake, which can brake on its own under load. The pawl meshes with the ratchet under the action of the spring, ensuring safe operation of the brake.

Features

Compliant with international standards, safe, reliable, and durable.

Good performance and easy maintenance.

It has high toughness, small size, light weight, and is easy to carry.

Low hand pull and high mechanical strength.

Compact and advanced structure with beautiful appearance.

Lifting goods in areas without power supply.

Powerful functionality.

Technical Data

| SPECIFICATIONPN | ||||||||||||

| Type | HS2-C0.5 | HSZ-CI | HS2-C¹.5 | HSZ-C2 | HSZ-C3 | HS2-C5 | HS2-CIO | HSZ-Ci5 | HSZ-620 | HSZ-C30 | ||

| Rated lifting capacity(t) | 0.5 | 1 | 1.5 | 2 | 3 | 5 | 10 | 15 | 20 | 30 | ||

| Test load(kn) | 7.5 | 15 | 22.5 | 30 | 37.5 | 62.5 | 125 | 187.5 | 250 | 375 | ||

| Lifting height(m) | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | ||

| Rated load hand pulling force(n) | 210 | 330 | 385 | 380 | 385 | 420 | 435 | 460 | 450×2 | 450X2 | ||

| Rows of lifting chain | 1 | 1 | 1 | 2 | 2 | 2 | 4 | 6 | 6 | 12 | ||

| Main dimensions | A | 147 | 147 | 163 | 147 | 183 | 215 | 363 | 400 | 590 | 692 | |

| B | 126 | 126 | 141 | 126 | 141 | 163 | 168 | 96 | 195 | 315 | ||

| K | 24 | 28 | 34 | 34 | 8 | 48 | 64 | 64 | 75 | 85 | ||

| H(min) | 300 | 306 | 390 | 400 | 483 | 616 | 720 | 280 | 1000 | 1380 | ||

| Net weight(kg) | 10 | 10.5 | 16 | 6 | 25 | 28 | 72 | 28 | 168 | 220 | ||

| Lifting height. Weight for each additional one meter(kg) | 1.7 | 1.7 | 2.3 | 2.5 | 3.7 | 5.3 | 9.7 | 14 | 19.4 | 28.2 | ||

Components

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.