European Standard Electric Hoist

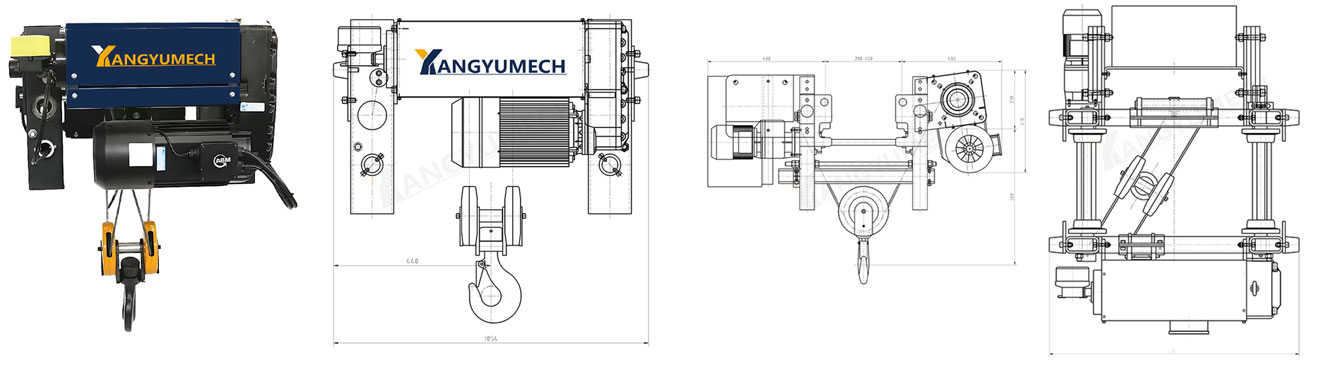

European Type Electric Hoist is designed and manufactured according to international standards with modular and compact design, integrated 3 (motor + reducer + brake) in 1 motor, optimized force distribution to realize the fast and precise positioning fun

Capacity(kg): 1000-12500

Working Class(FEM): 1Am-4m

Working Class (ISO/GB): M4-M7

Lifting Height (m): 6/9 12/18

Trolley Speed (m/min): 2-20

Description

European standard high duty electric hoist is used for Mechanical Workshop. It employs motor of hoisting mechanism and reducer imported ABM from Germany. The integrated and compact design of hoisting motor, reducer, reel and limit switch saves space for the user. Modular design increases the reliability of mechanism meanwhile reduces the time and cost for maintaining.

The European Standard Electric Wire Rope Hoist is an innovative solution designed to meet the demanding needs of modern industrial environments. Built to European standards, this hoist provides exceptional safety and performance, making it ideal for a variety of applications including factories, warehouses, and shipyards.

With a load capacity ranging from 5 to 80 tons, the European Standard Electric Wire Rope Hoist is capable of handling heavy loads with ease. The lifting height can be customized between 6 and 48 meters, and the hoist offers variable speeds from 2.6 to 13.3 m/min, ensuring precise and efficient operation. The hoist is constructed using aviation-grade steel wire ropes and alloy drums, ensuring a secure lifting structure and long-term durability. The low noise planetary gearbox provides smooth and stable movement, while the optimized transmission efficiency enhances overall performance.

Designed for longevity, can perform for 20,000 to 500,000 duty cycles, making it a cost-effective and reliable investment for any industrial operation. Whether lifting heavy machinery, positioning equipment, or handling materials, the KRQ7 European Standard Electric Wire Rope Hoist delivers superior performance and safety.

Features

European standards certified design and safety mechanisms

Load capacity ranging from 5 ton to 80 tons

Customizable lifting height from 6 to 48 meters

Hoist speed adjustable from 2.6 to 13.3 m/min

Long durability from 20,000 to 500,000 duty cycles

Multiple safety features like emergency brake, overload limiter

Optional control modes including push button, radio remote and cab room

Smooth stable operation with low noise serious planetary gearbox

Accessories and components customization available

Technical Data

| Rated load S. W.L (Kg) | Work level | Lifting Height | Lifting speed | Traveling speed | |

| FEM | ISO | m | m/min | m/min | |

| 2000 | 1 AM- 4M | M3-M6 | 6/9/12/15/18 | 0. 8/5 | 2~20 |

| 3200 | 1 AM- 4M | M3-M6 | 6/9/12/15/18 | 0. 8/5 | 2~20 |

| 5000 | 1 AM-4M | M3-M6 | 6/9/12/15/18 | 0. 8/5 | 2~20 |

| 6300 | 1 AM-4M | M3-M6 | 6/9/12/15/18 | 0. 8/5 | 2~20 |

| 8000 | 1 AM-4M | M3-M6 | 6/9/12/15/18 | 0. 8/5 | 2~20 |

| 10000 | 1 AM-4M | M3-M6 | 6/9/12/15/18 | 0. 8/5 | 2~20 |

| 12500 | 1 AM-3M | M3-M5 | 6/9/12/15/18 | 0. 8/5 | 2~20 |

| 16000 | 1 AM-3M | M3-M5 | 6/9/12/15/18 | 0. 66/4 | 2~20 |

| 20000 | 1 AM-3M | M3-M5 | 6/9/12/15/18 | 0. 66/4 | 2~20 |

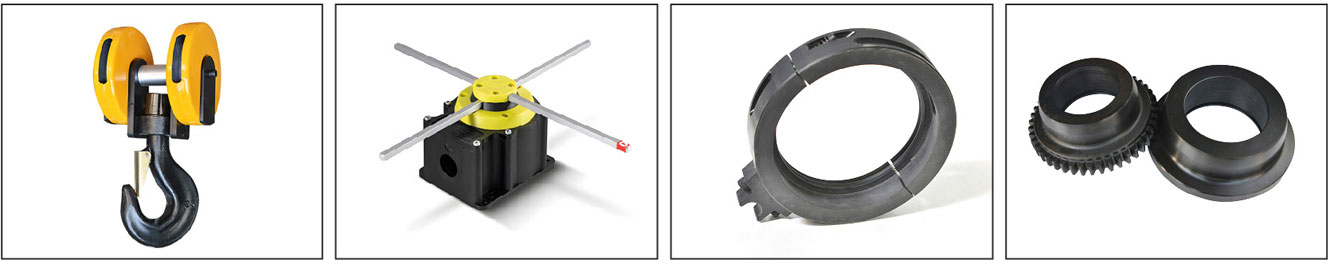

Components

-

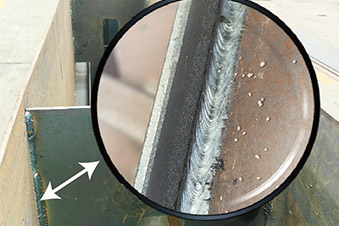

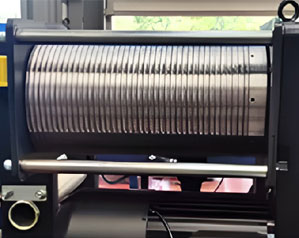

Reel

The reel is made of high-quality seamless pipes and processed by numeral control machine after the special finishing, the rope groove on reel works in coordination with the rope guide to efficiently prevent rope looseing and tangling.

-

Steel rope

Employ imported steel rope with high strength which has tensile strength of 2160 kN/mm2, with good safety performance and a long service life.

-

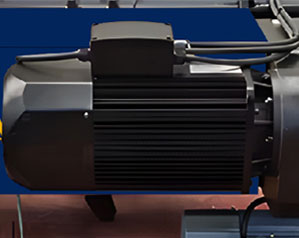

Motor

The hoisting mechanism adopts a double-winding pole-changing squirrel-cage motor and a German-imported three-in-one reducer to achieve a speed ratio of 1:6. A thermal resistor is embedded in the winding group of the motor to prevent possible overheating of the motor.

-

Control model

Can use control handle with pendant line, wireless remote control, or cabin control.

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.