Home > Products > Overhead Crane > European Single Girder Overhead Crane

European Single Girder Overhead Crane

European Single Girder Overhead Crane is designed with high configuration, which is developed with advanced design technology referring to European FEM standard. Cranes are mainly made up by single main beams, end beams, hoist, electrical parts and other

Span: 7.5-25.5 M

Capacity: 1--18.5 T

Traveling Rail: P24~P43

Description

Compared to traditional single-beam cranes, European-style cranes have the most reasonable structure for steel structures, hoisting mechanisms and accessories. Large-scale use of high-strength materials, while reducing its total weight at the same time, but also improve the machine carrying capacity. Limit distance from hook to both sides is short but has large working arrange. With lower height above the rails, it makes full use of space of factory building.

Electric single girder European Hoist Type Overhead Crane could be widely used to handle materials in many industries' workshop and warehouse. Such as machinery manufacture, warehouse, logistic, food, paper making, electronics industries workshop and other material handling situations. The lifting hoist adopts M5 working class with double lifting speed. motor with ABM German brand motor. Travelling motor uses SEW European brand in one motor gear motors. Cross and long traveling are variable travelling speed. Electric parts adopt Siemens brand. The protection class is IP 54 high class. The working class can reach to A5/M5 class under ISO standard.

Features

1.Lightweight structure, excellent performance, advanced design concept, effectively improve space utilization.

2.Made of high quality steel, durable and corrosion resistant.

3.Complete standard configuration, stable running, fast positioning, stable and safe operation.

4.Simple maintenance, low installation and maintenance costs, and long service life.

Technical Data

|

Span |

m |

7.5 |

10.5 |

13.5 |

16.5 |

19.5 |

22.5 |

25.5 |

|

Capacity |

t |

1--12.5T |

||||||

|

Max.Wheel Load |

kn |

13.5~90.94 |

||||||

|

Traveling Rail |

|

P24~P43 |

||||||

|

Trolley Weight |

kg |

405~740 |

||||||

|

Lifting Speed |

m/min |

0.8/5 |

0.8/5 |

0.8/5 |

0.8/5 |

0.8/5 |

0.8/5 |

0.8/5 |

|

Lifting Height |

m |

≥6 |

≥6 |

≥6 |

≥6 |

≥6 |

≥6 |

≥6 |

|

Trolley Speed |

m/min |

2- 20 |

3- 20 |

2- 20 |

2 - 20 |

2 -20 |

2 -20 |

2 -20 |

|

Crane Speed |

m/min |

3 -30 |

3 -30 |

3 -30 |

3 -30 |

3 -30 |

3 -30 |

3 -30 |

|

Total Power |

kw |

4.31 |

4.31 |

4.31 |

4.31 |

4.67 |

4.67 |

4.67 |

|

Total Weight |

1781~12086 |

|||||||

|

Working Duty |

M5 |

|||||||

Components

-

European Electric Hoist

-

Main Girder

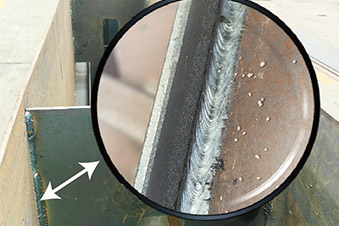

Main Girder will have sandblast derusting and painted with zinc rich epoxy primer.

Main Girder is cut by plasma numerical control cutting machine.

The butt weld of tension flange shall undergo ultrasonic or x-ray flaw detection as specified. -

Ground Girder

Ground Girder will have sandblast derusting and painted with zinc rich epoxy primer.

The wheels of ground girder are produced in special vacuum casting workshop which make wheels more elastic and outer surface hard-wearing and durable. -

Control model

Can use control handle with pendant line, wireless remote control, or cabin control.

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.