Home > Products > Gantry Crane > European Single Girder Gantry Crane

European Single Girder Gantry Crane

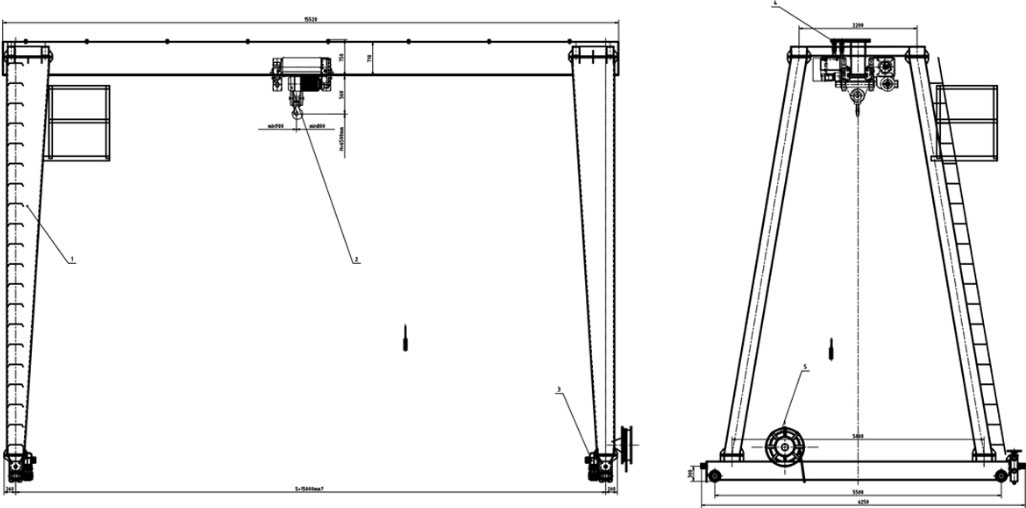

European Single Girder Gantry Crane is a cost-effective alternative wherever the installation of overhead cranes is impractical due to a need for a raised runway structure. They are also an ideal supplement to overhead cranes at the workstation level

Crane Capacity 3 ton, 5 ton, 8 ton, 10 ton, 12.5 ton, 16 ton and 20 ton

Crane Span 7.5 m to 28.5 m

Lifting Height 6m to 18m

Working Class: A5, A6, A7

Description

1.European single girder gantry crane is used together with European type electric hoist.

2.It's a track travelling small and medium-sized crane.Its proper lifting weight is 3~16 t, proper span is 12-30 m, Its proper working temperature is -20°C-+40°C.

3.European single girder gantry crane is a regular crane widely used at open ground and warehouse to load.

4.European-style gantry crane dead load can reduce by 20%~30%. The maximum wheel pressure can reduce by 15% ~ 20%. With the lightness structure it can cut the construction costs.

5.Gantry cranes are typically wheeled, which can run on rails or floor. A workstation or portable gantry crane is a very versatile gantry. The height on many models may be adjustable. Since it is usually wheeled, it is easy to move around to reach every corner of workshop .

6.European single girder gantry crane plans are not restricted by the site and can play the biggest advantage in the outdoor environment. Both sides of the main beam can extend the outer suspension. Hoisting mechanism can run beyond the span of operations. It is mainly used for loading and unloading operations of outdoor freight yards, material yards and bulk cargoes. Gantry cranes have the characteristics of high site utilization, wide operating range, strong universality.

Yangyumech Crane can provide you European type single girder gantry crane and European type double girder gantry crane according to your demands.

Features

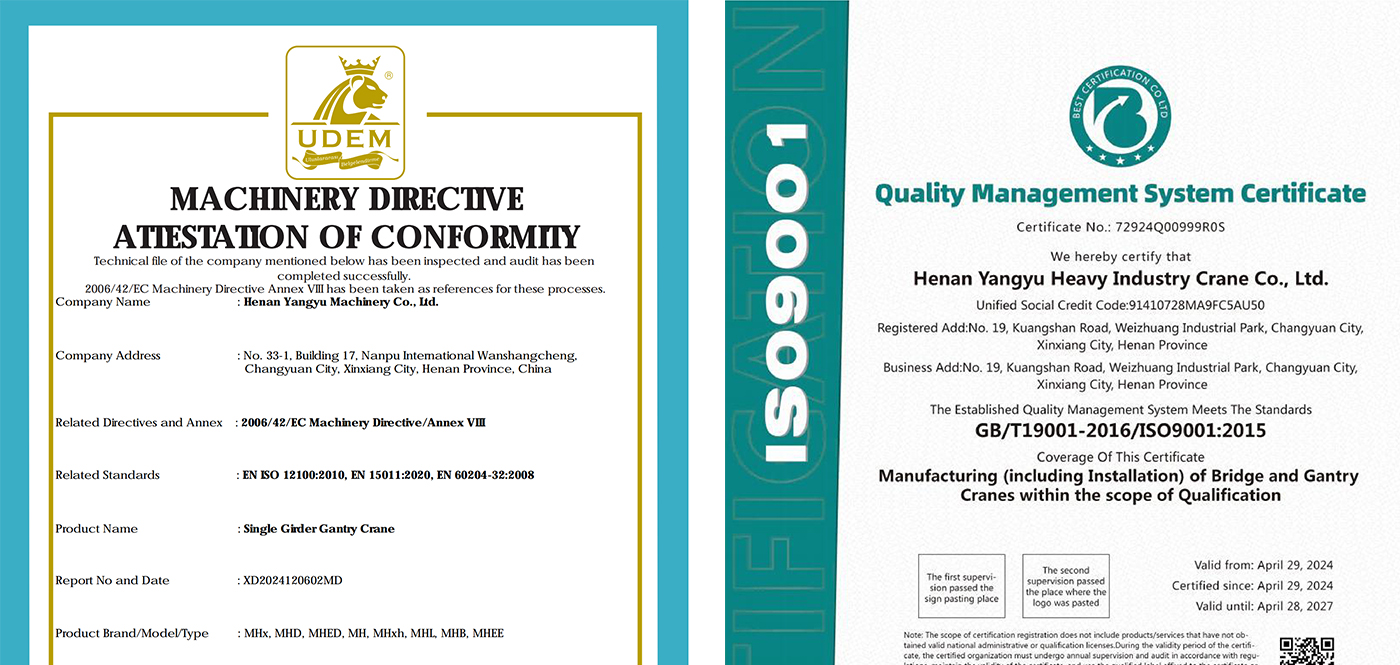

1. International standard production, operating frequency conversion control.

2. All steel structure plate will do shot blasting, surface finish Sa2 class.

3. Painting two times of zinc-rich epoxy, which have good appearance and fine gloss

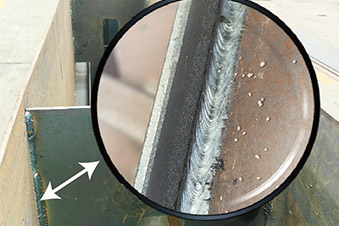

4. The welding adopts gas protection or submerged arc welding, and the welding seam UT is non-destructive inspection.

5. All electric hoists are tested before leaving the factory. Dynamic load 1.1x/static load 1.25x.

6. Standard safety monitoring, sound-light alarm and infrared collision prevention ensure the safety of crane transportation.

7. The lifting height is greater than 15 meters with an anemometer, and the span is greater than 35m with flexible legs

8. Electronic correction.

9. The power supply can be supplied by cable, sliding contact line.

Technical Data

| Capacity | 1t | 2t | 3.5t | 5t | 10t | 16t | 20t |

| Span | 7-30m | ||||||

| Lifting height | 6-12m | 9-12m | |||||

| Work Duty | |||||||

| Lifting Speed | 0.6/4 m/min | ||||||

| Hoist Traveling speed | |||||||

| Crane Traveling Speed | |||||||

| Rail | P24 | P30 | P43 | ||||

Components

-

European Electric Hoist

-

Main Girder

Main Girder will have sandblast derusting and painted with zinc rich epoxy primer.

Main Girder is cut by plasma numerical control cutting machine.

The butt weld of tension flange shall undergo ultrasonic or x-ray flaw detection as specified. -

Ground Girder

Ground Girder will have sandblast derusting and painted with zinc rich epoxy primer.

The wheels of ground girder are produced in special vacuum casting workshop which make wheels more elastic and outer surface hard-wearing and durable. -

Control model

Can use control handle with pendant line, wireless remote control, or cabin control.

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.