Home > Products > Overhead Crane > Double Girder Overhead Crane

Double Girder Overhead Crane

The 3 - 32t cranes with a span of 7.5 - 31.5m produced by our company. The main lifting device is a seated type hoist. Compared with the same type of electric double-girder overhead traveling crane, it has the characteristics of light weight and low cost, and is suitable for low-height workshops where the QD type is not suitable for installation.

Capacity: 3t-125t

Customized:YES

Description

LH type electric double-girder overhead traveling crane: The LH type 3 - 32t cranes with a span of 7.5 - 31.5m produced by our company. The main lifting device is a seated type hoist. Compared with the same type of QD electric double-girder overhead traveling crane, it has the characteristics of light weight and low cost, and is suitable for low-height workshops where the QD type is not suitable for installation.

QD type electric double-girder overhead traveling crane: The electric double-girder crane is composed of four parts: the bridge, the trolley, the traveling mechanism of the large vehicle, and the electrical equipment. This product is suitable for workshops, freight yards and warehouses in departments such as stations, ports, industrial and mining enterprises, etc., and is used for lifting, transporting and loading and unloading various materials within the fixed span.

According to different environments and different uses, it is divided into many forms such as slow speed, explosion-proof, insulation, electromagnetic, grab bucket, double trolley, dual-purpose, and triple-purpose. Our company produces various double-girder overhead traveling cranes.

Energy-saving (European-style) crane: The energy-saving (European-style) crane has the characteristics of light dead weight, compact structure and low energy consumption. A trolley and a lifting mechanism, trolley traveling mechanism and large vehicle traveling mechanism are set on the bridge to realize the handling of materials and objects in three-dimensional space. With a unique design concept, it has the characteristics of small size, light weight and small wheel pressure.

|

Features

Flexible, adaptable through different installation variants

Low-maintenance, low-noise direct drive with disc brake and centrifugal mass

Smooth starting and braking characteristics: with frequency inverter as an option

Explosion-proof versions or off-standard solutions through engineering

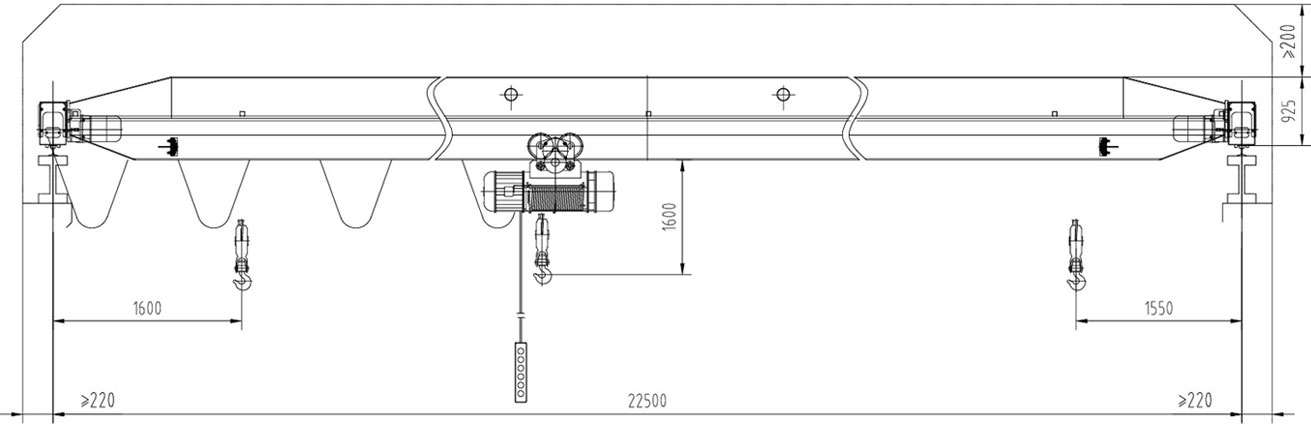

Technical Data

| Lifting capacity | t | 32/5 | ||||||||

| Operatlonal method | Ground controllg;Room controlling | |||||||||

| Main hook lfting speed | m/min | 2.4(0.24/2.4) | ||||||||

| Aux.hook lifting speed | m/min | 8(0.8/8) | ||||||||

| Crab travelling speed | m/min | 20 | ||||||||

| Crane travelling speed | Ground | m/min | 20 | |||||||

| Room | m/min | 30 | ||||||||

| Electric hoist | HC(HM);CD₁ (MD₁) | |||||||||

| Lifting height | m | 9、12、8 | ||||||||

| Working system | A3 | |||||||||

| Power source | Three phase.AC380V 50HZ | |||||||||

| Steel track | P43 | |||||||||

| Span | m | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | ||

| Max.wheel pressure | Ground | kN | 158.7 | 175.2 | 186.6 | 196.4 | 207.4 | 217.7 | 222.4 | |

| Room | kN | 160.6 | 177.1 | 188.5 | 198.3 | 209.4 | 219.7 | 224.3 | ||

| Crane weight | Ground | kg | 11575 | 13394 | 15372 | 17560 | 20790 | 24107 | 25316 | |

| Room | kg | 12350 | 14169 | 16147 | 18325 | 21596 | 24892 | 26081 | ||

| Total power | Ground | kW | 36.4 | |||||||

| Room | kW | 38.4 | 39.6 | |||||||

| Basic dimensions | B | mm | 4820 | 5020 | ||||||

| W | mm | 3800 | 4000 | |||||||

| K | mm | 2000 | ||||||||

| E | mm | 2700 | ||||||||

| H | mm | 1863 | 1963 | |||||||

| H1 | mm | 750 | 850 | |||||||

| H2 | mm | 151 | 251 | 355 | 457 | 457 | 609 | 709 | ||

| H3 | mm | 2676 | 2776 | 2880 | 2982 | 2982 | 3134 | 3234 | ||

| H4 | mm | 542 | 442 | |||||||

| b | mm | 230 | ||||||||

| S1 | mm | 1705 | ||||||||

| S2 | mm | 1865 | ||||||||

Components

-

Electric Trolley

Hoist trolley usually installed on the heavy duty bridge crane or gantry crane as a lifting mechanism. It has a simple structure and light weight. It’s mainly used in general hoisting, loading and unloading operations in machinery manufacturing workshops, warehouses, assembly and hydro-power station maintenance.

-

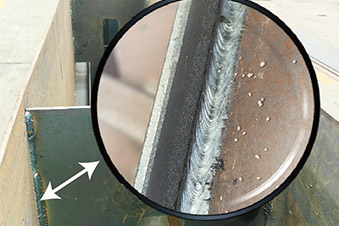

Main beam

The main beam is the crane's main load-bearing component, and the running track for the electric hoist. It is a triangular beam is weld by a support frame(welded by angle steel and other section steel) and an I-beam. The two sides of the span are designed with saddles connected to the outriggers, and there are rectangular steel plate connecting flanges. There are buffers at both ends of the main beam to ensure the safe operation of the trolley on the main beam.

-

Crane Hook

Crane hook is the most common type of spreader in lifting machinery. The crane hook is often suspended on the wire rope of the hoisting mechanism with the help of pulleys and other components. The crane hook should conform to the manufacturer's suggestions and must not be overloaded.

-

Crane Cab

The crane cab is the workplace of the crane operator and it undertakes a crucial role. The design of the cab fully considers the comfort and safety of the operator. It has a good view so that the operator can clearly observe the surrounding environment and operating conditions.

-

Control model

Can use control handle with pendant line, wireless remote control, or cabin control.

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.