Home > Products > Gantry Crane > Double Girder Gantry Crane

Double Girder Gantry Crane

Double girder gantry cranes High CAPACITY Stable Security... Double Girder Gantry Crane is suitable for loading and unloading in sites of open storage, material yard, railway freight station, port terminal and so on. It also can be equipped with a variety of special hooks for a variety of special oper

Lifting capacity: Up to 500ton

Lifting height: Up to 30m or customized

Lifting span: 3 to 35m; Working class: A5-A7

Working temperature: -20 to 40 degree C

Description

MG Type Double Girder Gantry Crane (Truss-type) is made up of bridge, trolley, crane traveling mechanism and electric system.Applies to highway, bridges, power station and other Construction workshops for general handling and lifting operations. All institutions are indoor controlling, crane electric form is devided into two kinds of cables and sliding contact line, you can choose any one when you order it.

Double girder gantry cranes ; It is preferred and used seriously in every branch of the industry due to its cost, ease of maintenance and repair,no capacity limit, no size limit, design and manufacture with desired features. Much higher lifting heights can be obtained compared to single-girder gantry cranes. Double girder gantry cranes can be produced as protruding or without protrusion.

Although Portal Cranes are generally used in open fields, they can also be used in the factory. It is an alternative application to overhead cranes in factory indoor areas. Gantry cranes has more advantages than jib cranes acoording to scanning area. Gantry cranes , also called marble cranes, are suitable for all kinds of lifting and stacking works in open areas.

Examples Of Our Double Girder Gantry Crane Installations

Features

Reasonable structure

Favorable performance

Smooth starting and stopping

Safe and reliable traveling

Low noise, commodious cabin and good view

Convenient maintenance, excellent exchange ability for parts and components

Saves electricity specifications

Our Gantry Cranes are completely designed by our own engineers in accordance with ISO, FEM and DIN norms. Mechanism selections are made in accordance with the desired lifting and running speeds and working class. Bridge beam deflection is calculated as 1/1000 at most. By having a quieter and more sensitive bearing system compared to its alternatives, it increases the life of the roller, wheel and gear box, and thanks to the adjustable wheel center, it can provide +/- 15 mm movement in the centers where there are rail defects.

Technical Data

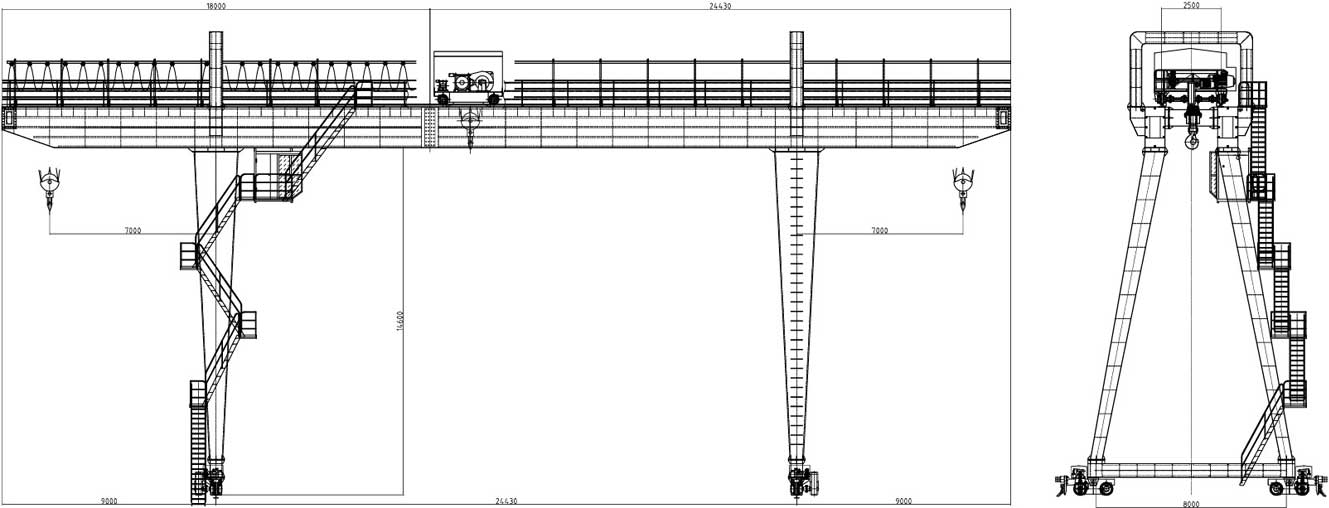

| Lifting capacity | t | (lower by sling)32/10 | Main Dimensions(mm) | ||

| Span(S) | mm | 30000m-21000m, Continuous variable span | Main Dimensions | ||

| Lifting Height(H) | 40m(on the ground 10m, Underground30m) | K | 7000 | ||

| Working system | A7(A6) | W | 8500 | ||

| Speed | Hoisting | m/min | fully loaded 1-12 No-load 1-20 | B | 9400 |

| Hoisting | fully loaded 1-15 No-load 1-25 | A | 600 | ||

| Crab travelling | fully loaded 2-20 No-load 3-30 | H | 100000 | ||

| Trolley travelling | fully loaded 3-30 No-load 3.5-35 | L1 | 9000 | ||

| Electric motor | Hoisting | KW | 90Kw | C1 | 5000 |

| Hoisting | 30Kw | L2 | 10000 | ||

| Crab travelling | 2x4Kw | C2 | 5000 | ||

| Trolley travelling | 4x7.5Kw | H1 | 4000 | ||

| Trolley travelling | KN | 290(260) | |||

|

Number of wheels

|

8(4) | ||||

| Steel track Recommended | P38-P43 | ||||

| Power source | Three-phase alternating current 3-phase A.C. 50HZ 380V | ||||

Components

-

-

Electric Trolley

Hoist trolley usually installed on the heavy duty bridge crane or gantry crane as a lifting mechanism. It has a simple structure and light weight. It’s mainly used in general hoisting, loading and unloading operations in machinery manufacturing workshops, warehouses, assembly and hydro-power station maintenance.

-

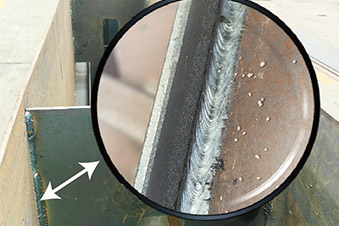

Main beam

The main beam is the crane's main load-bearing component, and the running track for the electric hoist. It is a triangular beam is weld by a support frame(welded by angle steel and other section steel) and an I-beam. The two sides of the span are designed with saddles connected to the outriggers, and there are rectangular steel plate connecting flanges. There are buffers at both ends of the main beam to ensure the safe operation of the trolley on the main beam.

-

Crane Hook

Crane hook is the most common type of spreader in lifting machinery. The crane hook is often suspended on the wire rope of the hoisting mechanism with the help of pulleys and other components. The crane hook should conform to the manufacturer's suggestions and must not be overloaded.

-

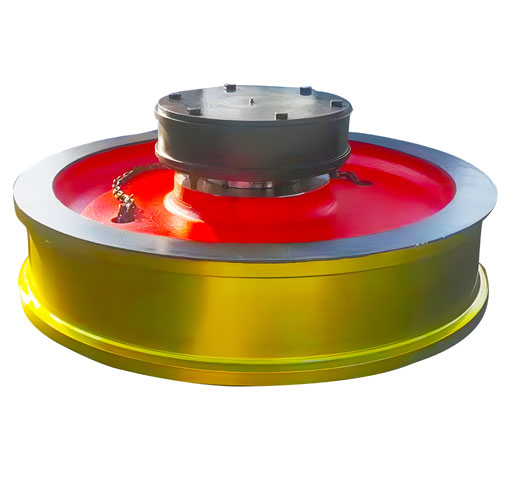

Wheel Set

The wheel set is a mechanical device consisting of a wheel and a shaft, a bearing and a bearing housing. The crane wheel set is generally used for the vehicle to support the crane and the load, and at the same time, the crane is allowed to perform the reciprocating running operation on the specified track.

-

Crane Cab

The crane cab is the workplace of the crane operator and it undertakes a crucial role. The design of the cab fully considers the comfort and safety of the operator. It has a good view so that the operator can clearly observe the surrounding environment and operating conditions.

-

Control model

Can use control handle with pendant line, wireless remote control, or cabin control.

-

industry

case Center

our service

-

Equipment Manufacture

The annual output is more than 900,00 units, with more than 100 sets of advanced equipment, and the full product line automation rate reaches 80% .

-

Construction Management

Control project delivery, cost and quality ,from design to end of building ,according to customer's technical requirements

-

Technical Trainning

Provide comprehensive training, including equipment structure and principle training, installation specification training, etc., also 24H after-sales technical supporting, to ensure equipment stable operation on site

-

Spare Parts/Fast delivery

We provide over 220 types of cranes and their related products, saving customers’ purchasing time.